Barcode Basics: What to Know About Barcodes and UPCs for Product Labels

A barcode and a UPC may not be the most attractive part of your product label, but they play an important role for your business. A good barcode with an appropriate UPC will make it easy for you or a separate vendor to scan your labels and sell your goods. This makes it very important to make sure your barcodes are set for success. Here’s what you should know to make sure your barcodes and UPCs are ready to head out into the market.

What Goes into a Barcode and UPC?

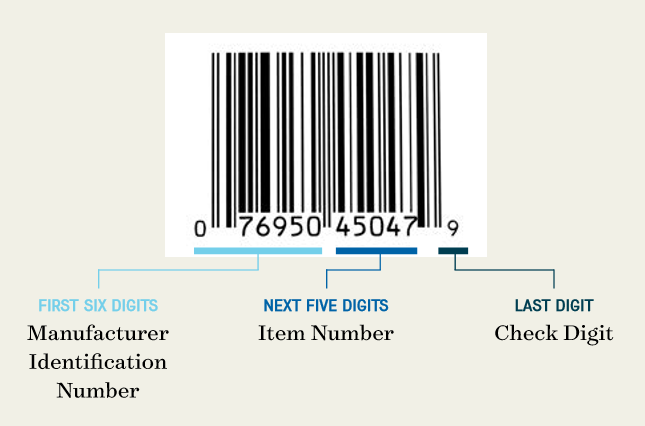

A barcode and a UPC are two different elements that work together to identify a product. The UPC, which stands for universal product code, is a 12-digit number assigned to merchandise, while the barcode is the machine-readable version of that number. Different parts of that 12-digit code play different roles.

- First six digits – the manufacturer identification number

- Next five digits – the item number

- Last digit – the check digit

Looking for Custom Labels?

We put our all into every custom label we make. No exceptions. And with no minimum order quantities and a 5-day turnaround for digital label printing, we take pride in helping you perfect your first impression.

Request a Quote Get a Sample Pack

Manufacturers can apply for UPCs from the Uniform Code Council. After approval, a manufacturer can pay an annual fee to become a part of the UPC system and get its unique manufacturer identification number that will be used for all its barcodes. The item number is specific to each product. The manufacturer is responsible for issuing those numbers and avoiding any duplication of numbers for different SKUs. Finally, the digit check is a single number to confirm the integrity of your barcode number. You can determine the exact number for a product with GS1’s check digit calculator.

How to Make Sure Your Label’s Barcode and UPC Work

Barcodes are graded on a scale from A to F. As you may expect, the higher your grade, the better your barcode and UPC will be for business. Here are some key considerations to help improve your barcode and UPC for your product labels.

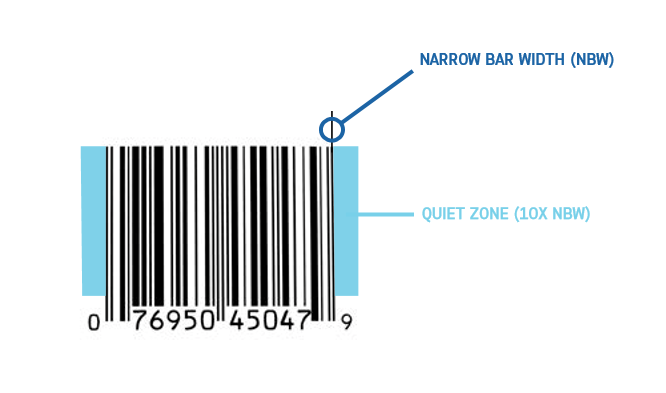

Respect the quiet zone

Every barcode has what’s called a “quiet zone.” This space is the area around the barcode that should be clear of any texts, graphics, or other printed elements. If you don’t afford a barcode a proper quiet zone, a scanner can accidentally read some other element in the surrounding artwork and cause an error.

To prevent any issues, it’s important to give each barcode the proper amount of space. In general, the quiet zone should be the larger of the following two measurements.

- 10 times the width of the most narrow bar in the barcode

- An eighth of an inch

Use the right colors for your barcode

While utilizing various colors can help lead to an eye-catching label, barcodes should follow a very simple color scheme. It’s best to stick with black text on a white box for any barcode to help ensure scanning success. Warm colors won’t work well with red laser scanners, so sticking to black on white will help you avoid potential problems in the future.

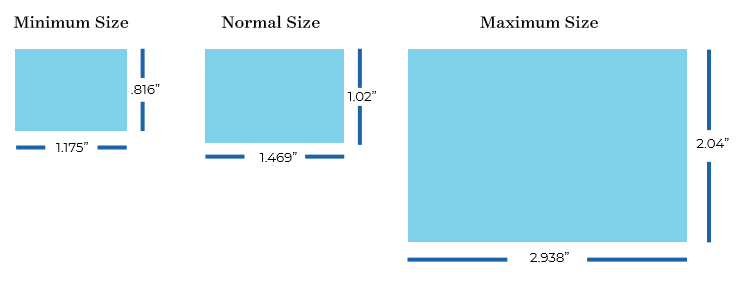

Pay attention to barcode size

It’s important to make sure the your barcode isn’t too big or too small for both your label and scanners. In general, bigger barcodes and UPCs are easier to scan, but your options may depend on your design and total label space. A typical barcode measures 1.469 inches wide by 1.02 inches high, but you can adjust the size as necessary as long as you stay between the following minimum and maximum recommended barcode sizes.

- Minimum – 1.175” wide by .816” high

- Maximum – 2.938” wide by 2.04” high

Send your barcodes to the printer in the right format

Once you have your label design with an appropriate barcode, it’s time to send It along to a printing company. However, there are specific rules as to how you should send that information. In addition to sending the appropriate art files for your label, you’ll also need to deliver the barcode(s) in one of the following forms.

- An image file of the barcode you’ve received from the provider

- An Excel document with a list of UPC numbers

- A PDF or EPS of the barcodes

Make Sure Your Labels are Perfect for Your Products

Preparing a barcode and UPC for a product label is one of many important parts in the labeling process. Once you take all the steps to make sure your design is ready for production, it’s time to find a good printing company to give you the quality labels you deserve.

At Blue Label, we take all the steps necessary to not only print stunning labels, but also to check and make sure that everything is right before we print your full order. To help ensure that your barcodes are ready for the market, we’ll print out example labels and test them with scanners to make sure they work. After review, we’ll grade your barcodes and double check that your UPC matches the bars. If we notice any problems, we’ll notify you so that you can amend the issue before we print your run.

Ready to invest in quality product labels for your business? We’re happy to help. Contact us today to talk to us about your next labeling project.