Making Waterproof Labels for Bottles: Factors for Water Resistance

- adhesives

- bottle labels

- waterproof labels

⚞ The Highlights:

- Pick a synthetic material like polypropylene or polyester if your labels need to stand up to constant moisture and wear

- Use protective coatings or laminates so your text and graphics stay crisp even if the label gets wet

- Factor in temperature swings and the product’s environment before choosing an adhesive, so your labels won’t peel or smudge over time

After investing time and money to create great labels for your products, it would be a shame for them to peel off your container. Certain products are destined to encounter moisture, whether they sit in a cooler, sweat after being refrigerated, or encounter water during the application process.

While the majority of product labels don’t play well with water, there are measures that companies can take to protect their designs from a sad, soggy ending. Let’s break down a variety of factors that can help your labels stay strong and look great even after they’ve been exposed to moisture.

The Truth About “Waterproof” Labels for Bottles

Before we get too far, it’s important to address the proverbial elephant in the room—there is no such thing as a truly waterproof bottle label. Water and other fluids will impact even the most water-resistant bottle labels at some point. As such, you can’t guarantee complete protection with a simple label material.

As you research packaging for your product, you’ll likely come across both waterproof labels and water-resistant labels. So what’s the difference?

Waterproof labels offer near complete protection against water, making them suitable for products that are submerged or exposed to water continuously, while water-resistant labels can withstand moisture to a certain degree but will eventually succumb to prolonged exposure.

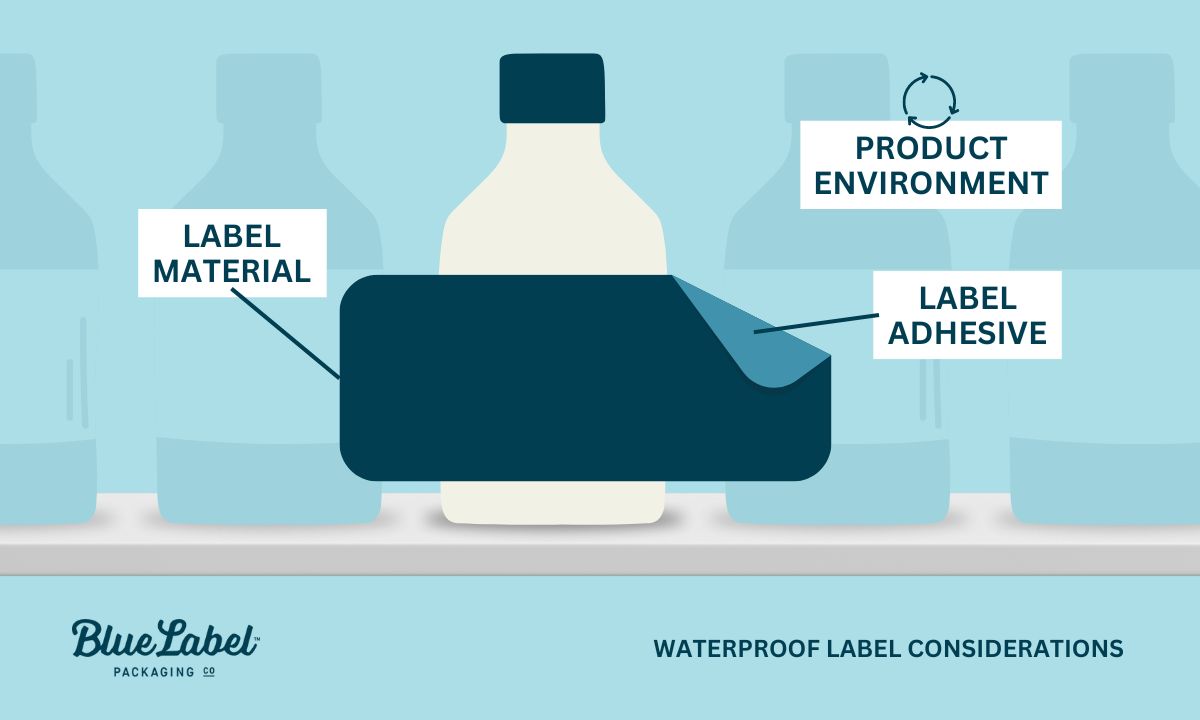

While complete water resistance isn’t attainable, that doesn’t mean there aren’t means to protect your packaging as much as possible. There are several ways to make your labels as water and oil-resistant as possible, including the following considerations:

- Label material

- Label adhesive

- Environmental considerations

Choose a Label Material

There are a wide range of label materials available, but the majority of them fall under one of two categories: paper or film. Both groups offer various benefits, but one type typically fares much better against water and other fluids than the other.

Paper is a great choice for companies looking for a versatile, cost-effective material, but there’s one big problem—paper has a tendency to disintegrate in water. There are specific styles of paper with a higher wet strength that can slow water penetration. However, there is no waterproof label paper and even the most water resistant paper substrates will become fully saturated over time.

Best Materials for Water Resistance: Film Stocks

If you need water resistance, we strongly suggest sticking with film stocks. Unlike paper, film stocks won’t absorb water, making them as waterproof as you can get for a bottle label. From shrink sleeves to roll labels, there are a few different film materials that are much better fits for products dealing with moisture.

- Polypropylenes (BOPP): A rigid film that features high tear resistance and is a great fit for beverages and other products that will encounter moisture.

- Polyester (PET): A film designed for maximum durability that is great for products used outdoors.

- Polyolefin: An extremely soft and flexible film perfect for squeeze applications, such as bottles that will end up in the shower or other wet environments.

- Waterproof vinyl: Vinyl boasts a number of benefits, including water resistance, durability, flexibility, and temperature resistance. Vinyl labels can even leverage a matte finish while maintaining the protection needed to resist moisture.

Regardless of your choice, the simple logic is that film is much better at resisting water than paper. As such, a film label is a great start for any bottles that will encounter moisture either before, during, or after application.

Label Finishes for Increased Durability

Several label finishing techniques can enhance the waterproofing and durability of a product label.

Applying a gloss finish, for example, adds a protective layer that repels water while giving the label a shiny appearance that catches the eye.

For an even more pronounced effect, ultra-gloss finishes increase this protection, creating a nearly impermeable barrier against moisture and wear.

Consider Label Stock Thickness

The effectiveness of a label’s waterproof or water-resistant properties is also influenced by its material thickness. Thicker labels can provide a more substantial barrier against moisture (though their resistance to moisture also depends on how porous the material is, its structural integrity upon wetting, and the ability to achieve secure edge sealing when applying the label).

As you’ll see in the next section, the choice of adhesive plays an important role in maintaining label adherence under moist conditions, with thicker labels necessitating stronger adhesives to counteract potential separation challenges.

Find an Appropriate Label Adhesive

Water, oil, and other wet substances can put you in a bind when you choose an adhesive for your labels. Even if your label itself is water resistant, a label adhesive needs to be able to withstand those substances. Everything from regular moisture to complete submersion can pose problems. With the wrong adhesive, you’ll be stuck with a label that’s falling off the bottle.

One drawback is that the presence of water may eliminate certain types of adhesives from your selection. For example, humidity and wet environments can pose problems for removable labels, so you may want to avoid them if you want a truly waterproof label.

Fortunately, there are moisture-resistant permanent adhesives designed to specifically combat this issue. There are a variety of factors that will impact exactly which adhesive works best—the amount of exposure, how often exposure is expected to happen, which types of fluids will pose problems, etc. Once that information is identified, a label printing expert can help you pair the right adhesive with your product.

Plan Around Your Environment

When there’s water and other fluids, there are other potential environmental issues that can create problems for your label. There are a few main considerations that you’ll want to make when it comes to you where your products will go.

- Your application environment

- Shipping and storage environments

- Where and how your bottles are used

- The product itself

Application Environment

Your application process makes a major impact on your choice of adhesive, label material, liner, and more. That is especially true if your product will be wet going into the application process.

A wet-apply adhesive is a must in these scenarios. You also may need to factor in your product as well. For example, acidic or oily products can wreak havoc if you don’t account for them in the planning process.

Shipping and Storage

Proper shipping and storage is another factor that can be easily overlooked. All waterproof product labels should be stored in a temperature-controlled environment. Exact temperature and humidity levels vary based on your exact label, but too much humidity in a shipping truck or a warehouse will pose problems.

Shrink sleeves are especially sensitive to humidity and other environmental factors, so make sure to keep them safe before application.

Product Usage and Application

Finally, you need to factor in just where your bottles will go once consumers get a hold of them. If your products are going to encounter ice buckets, coolers, or other cold storage places, you’ll need something stronger than a standard adhesive. A more aggressive, freezer-grade label adhesive will be able to withstand these conditions.

Other products may have very different issues, such as a bottle of conditioner. Certain health and beauty labels will sit in the shower and encounter other cleaning chemicals. These products need to withstand a hot, steamy environment along with oils and other substances.

Sunscreen bottles need waterproof capabilities at the beach or pool, but they also should have some form of UV resistance.

Product Contents

You should also consider whether the product itself may impact the label. For example, the oil found in products like sunscreen can affect the application and integrity of a label. Water-resistant capabilities are key, but you should always consider what will happen if some of your own product will leak out and interact with your label.

Why Waterproof Labels?

Whether your product is going to encounter light condensation or be fully submerged in water, waterproof labels will seem like an obvious choice for certain products. But the benefits go beyond simple resistance to moisture:

- Environmental conditions: The journey of a product from production to shelf can include a wide range of temperatures from hot and humid trucks to cool, damp freezers. The right labels help ensure product packaging integrity during this process.

- Durability: Without the right, durable materials for your product, packaging can smudge, peel, fade, and even grow mold over time.

- Legibility: When water meets the wrong materials, it can smudge or blur essential information on a package, including instructions, ingredients, or disclaimers.

Industries That Use Waterproof Labels

When you think waterproof, you might immediately think of beverage items that can be spilled, chilled in ice, stored in freezers, and generally submitted to a wide range of environmental conditions. But many industries and product types can benefit from waterproof labels, including:

- Beauty and cosmetic products: From beauty product labels to shampoo and soap labels, durability and legibility in wet environments is important.

- Household and cleaning products: Cleaning labels need to be able to withstand spills, drips, and frequent handling, and the safety information needs to remain visible and intact.

- Food products: Waterproof food grade labels help maintain important details in damp environments.

- Outdoor products: From rugged water bottles to camping equipment, product labels need to be able to withstand varying weather conditions.

Find the Right Label Printing Company

Whether you need custom waterproof labels for bottles, jars, or any other container, it’s essential that your packaging showcases the quality of your products and brand. At Blue Label Packaging, we have the equipment and expertise it takes to not only make your labels as water-resistant as possible, but also enhance your design to make lasting impressions on customers.

Ready to invest in the perfect bottle labels for your business? Contact us today to talk to one of our experts about high-quality, water-resistant labels.