What Does Die Cut Mean?

- Custom Designs

- die cutting

What is Die Cutting in Printing?

What is the die cut definition? Die cutting is a fabrication process that uses specialized machines and tools to convert stock material by cutting, forming, and shearing. In printing, die cuts are used to create custom shapes and designs for labels.

It starts with a part called, unsurprisingly, a die. A manufactured die is a specialized piece of metal tooling used to cut a specific shape out of a material. Think of it as a cookie cutter, but instead of a sheet of cookies, it is a sheet of label material. So the die cuts out the label, and excess material (called ‘matrix’) is removed. The ‘die line’ is the outline of where the die will cut, it is usually shown as a thick colored line in proofs.

Die cutting comes in many shapes and forms, some of which are better suited for labels than others. There are three major processes that you should know, so you can figure out what die cut process to use for your custom labels. The three processes that we’ll explore below are flatbed, rotary, and semi-rotary.

Flatbed Die Cutting

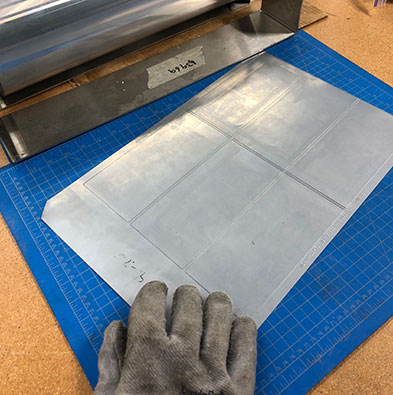

Flatbed die cutters use hydraulic presses and other lifting systems to press a die down on a sheet of material. Generally speaking, flatbed die cutting is used for low volume projects and larger sized products. Flatbed die presses tend to be better suited for heavier materials over 1/8” thick like felt, fiber, fabrics, and metals than for most label stocks.

Rotary and Semi-Rotary Die Cutting

Both rotary and semi-rotary use rollers to pass webs, which are long, flexible sheets of material through a machine so that a rolling die attached to a magnetic cylinder makes cuts to the material. However, we find that semi-rotary is better suited for cutting labels because its design makes it more capable of efficiently shearing custom labels.In the semi-rotary process, the cylindrical die rolls in a single direction, but the press moves the web back and forth while cuts are made. This movement allows a printer to use a single cylinder to make multiple cuts in a web. The process reduces the number of times the web needs to be run through a die-cutting system. That means that more complex cuts can be completed faster than in a standard rotary setup and quicker turnaround times for your printed items. After the web is cut, the excess material is pulled away, leaving only your labels behind.

Another important note for rotary and semi-rotary die cutting machines is that they can use either solid or flexible dies. While solid dies are steel cylinders with a design already built into the body of the die, flexible dies are thin sheets of steel that warp around a magnetic cylinder. This makes flexible dies less expensive, which is great for businesses looking for custom dies for their labels.

What to Consider for Die Cut Labels

The die cutting process can vary based on what you need. When it comes to die cutting labels, your design will dictate a lot about the process. For example, we have dies that are regularly available in all your typical shapes, such as circles, squares, etc. However, if you have a custom shape or specific designs elements, you’ll want to make sure that you work with a label converter that knows the ins and outs of die cutting. Let’s start with the shape of your design. While your label design may look awesome, you need to consider whether it will work when printed and cut. Here are some tips to consider for die cut labels:

- Avoid acute angles and sharp corners. They may tear when the matrix is removed after the die cutting process, resulting in avoidable waste.

- If you want holes within your label, leave enough space between the edge of your label and the hole. Thin strips of material are more likely to tear during removal.

- Add a bleed area that extends your design artwork at least 1/16” past the edges of your label. This helps ensure that there are no accidental white spaces.

- Make sure to correctly add a line of your shape into your Adobe Illustrator file. Mark the die line as a specific spot color and as a joined line on its own layer.

Need a Die Cut Label Printer?

When considering a custom label option, it’s always a good idea to work with a label converter that understands die cutting. If you or your designer still need help trying to figure out how to prepare your label design for die cutting, Blue Label Packaging can help. We have over 2,000 different dies available, and if none of those meet your needs, we have the expertise and capabilities to create a custom shape for your brand. Contact us today if you have any questions regarding die cutting or if you’re in need of custom label printing for your business.