A Guide to Water Bottle Labels: Material, Application, and Print Quality

Selecting the right custom labels for water bottles is about finding the right mix of looks, durability, and functionality. The right label can turn a simple bottle of water into a brand that consumers buy again and again.

Don’t think branding and packaging matters for a product as simple as water? Well just ask Fiji, LifeWtr, or Liquid Death, whose products rise above the expectations for just a bottle of water.

In this guide, we’ll walk through three areas to consider when choosing your custom labels: materials, adhesion and application, and print quality. These elements form the foundation of successful water bottle labeling strategies.

Material Choices for Bottled Water Labels

Choosing a material for your water bottles isn’t as simple as other products. Water bottles endure a wide variety of environments, from the hot temperatures of shipping trucks to cold refrigerators and buckets of half-melted ice.

Let’s take a look at some of the most popular material options.

Vinyl

Known for its robustness, vinyl stands up to moisture and wear-and-tear like a champ. Ideal for bottles that will see outdoor use or frequent handling, it combines longevity with vibrant print quality. Here are some of the characteristics that make vinyl an ideal label material for water bottles:

- Durability: Vinyl is highly durable and resistant to damage like tears, scratches, and abrasions.

- Water Resistance: Vinyl is water-resistant, so the label won’t deteriorate or peel off when the bottle gets wet.

- Flexibility: Vinyl is flexible, which allows it to conform easily to different sizes and shapes of water bottles.

- UV Resistance: Vinyl labels can be treated to withstand exposure to sunlight without fading or discoloration.

- Print Quality: Vinyl provides a smooth and clear surface for printing, allowing for high-quality, vibrant, and precise graphics in your labels.

- Adhesive Quality: Vinyl labels can be coated with various types of adhesives (we’ll touch on this later).

BOPP (Biaxially-Oriented Polypropylene)

A powerhouse in resisting water and oil, BOPP (sometimes known as “waterproof film labels”) is perfect for water bottles that need to maintain their look under wet conditions. Its flexibility makes it suitable for various shapes and sizes of bottles.

BOPP has many of the same characteristics that vinyl, including moisture resistance, durability, print quality, and cost-effectiveness, though there are a few differences:

- Chemical Resistance: BOPP is resistant to a wide range of chemicals, which can be helpful if your water bottles may come in contact with oils, greases, or other substances.

- Temperature Resistance: BOPP performs well in different temperature ranges—for water bottles that might be stored in extreme temperatures, from freezers to hot cars, this can be an added benefit.

- Clarity and Gloss: BOPP films can be manufactured to be crystal clear or with a high-gloss finish.

- Recyclability: BOPP is a type of polypropylene, which is recyclable. This makes BOPP labels a more environmentally friendly option compared to some other plastics.

- Cost-Effectiveness: Vinyl is a cost-effective option for producing labels, making it a popular choice when balancing looks with budget considerations.

PET (Polyester)

For those seeking strength plus clarity, PET materials offer superior resistance against water and UV rays—ensuring your label stays sharp and doesn’t fade over time. Once again, you’ll see similarities between PET and both vinyl and BOPP, but there are some key differentiators:

- Dimensional Stability: PET maintains its dimensions and does not shrink or stretch once applied, helping maintain the quality and appearance of the label over time.

- Sustainability: PET is also recyclable, which can appeal to eco-conscious consumers.

Finishing Options

While the label material is one part of the equation in protecting against the elements, label finishing can add not only protection, but extra visual appeal. Here are some of the options:

- Lamination: A clear plastic film is applied over the label, providing a protective layer and shielding the label from water, dirt, and UV rays. Lamination can come in gloss, matte, or satin finishes.

- UV Varnish: A UV varnish is another way to protect the printed area of the label or sticker from fading and wear. It also adds glossiness to the label, bringing out the vibrancy of colors. UV varnish can also be applied to selected areas (spot UV) for adding emphasis and texture contrast on specific parts of the label.

- Foil Stamping: This finishing process applies a metallic foil to the label to create a shiny effect. Foil stamping can be used for logos, brand names, or any elements where you want to catch the light and draw attention.

- Embossing and Debossing: These techniques create raised (embossed) or recessed (debossed) images on the label. They add texture and physical feel to the label.

- Thermal Coating: For labels that might be exposed to wide temperature ranges, a thermal protective coating can be applied to help resist the effects of high heat or freezing.

Application and Adhesion

Stickiness is not just about glue—it’s about labels staying put under various conditions. Here’s what you need to know to make sure your labels stay put under varying conditions:

Types of Adhesives

There are numerous adhesive choices for labels, but for water bottles, it boils down to finding an option that sticks well to plastic, metal, or glass surfaces. Each material interacts differently with adhesives:

- For Plastic: Look for adhesives designed specifically for synthetic surfaces which can bond firmly without peeling.

- For Metal: Opt for stronger glues capable of handling smooth, non-porous surfaces.

- For Glass: Choose water-resistant label adhesives since condensation can be a common issue.

Facing the Elements

Temperature fluctuations and moisture exposure are two big challenges in maintaining adhesive effectiveness:

- High heat can weaken some adhesives causing them to lose their grip. Acrylic adhesives are generally more resistant to temperature extremes, making them a better choice than rubber-based adhesives.

- Constant exposure to water demands waterproof or at least highly water-resistant glue formulations. Once again, acrylic adhesives make for a better choice for moist environments compared to rubber-based adhesives.

Permanent Adhesives vs. Removable Adhesives

When choosing between permanent and removable adhesives, it’s important to think about the intended use of the water bottles.

Permanent adhesives offer a strong, lasting bond that is ideal for most water bottles intended for long-term use or exposure to wide temperature ranges, frequent handling, moisture, and temperature variations.

On the other hand, removable adhesives provide the flexibility to peel off labels without leaving residue, which may be better for promotional items, temporary labeling, or for consumers who prefer a label-free bottle after purchase. Removable adhesives are also ideal where the label needs to be removed cleanly, such as in reusable water bottles that might be repurposed or recycled.

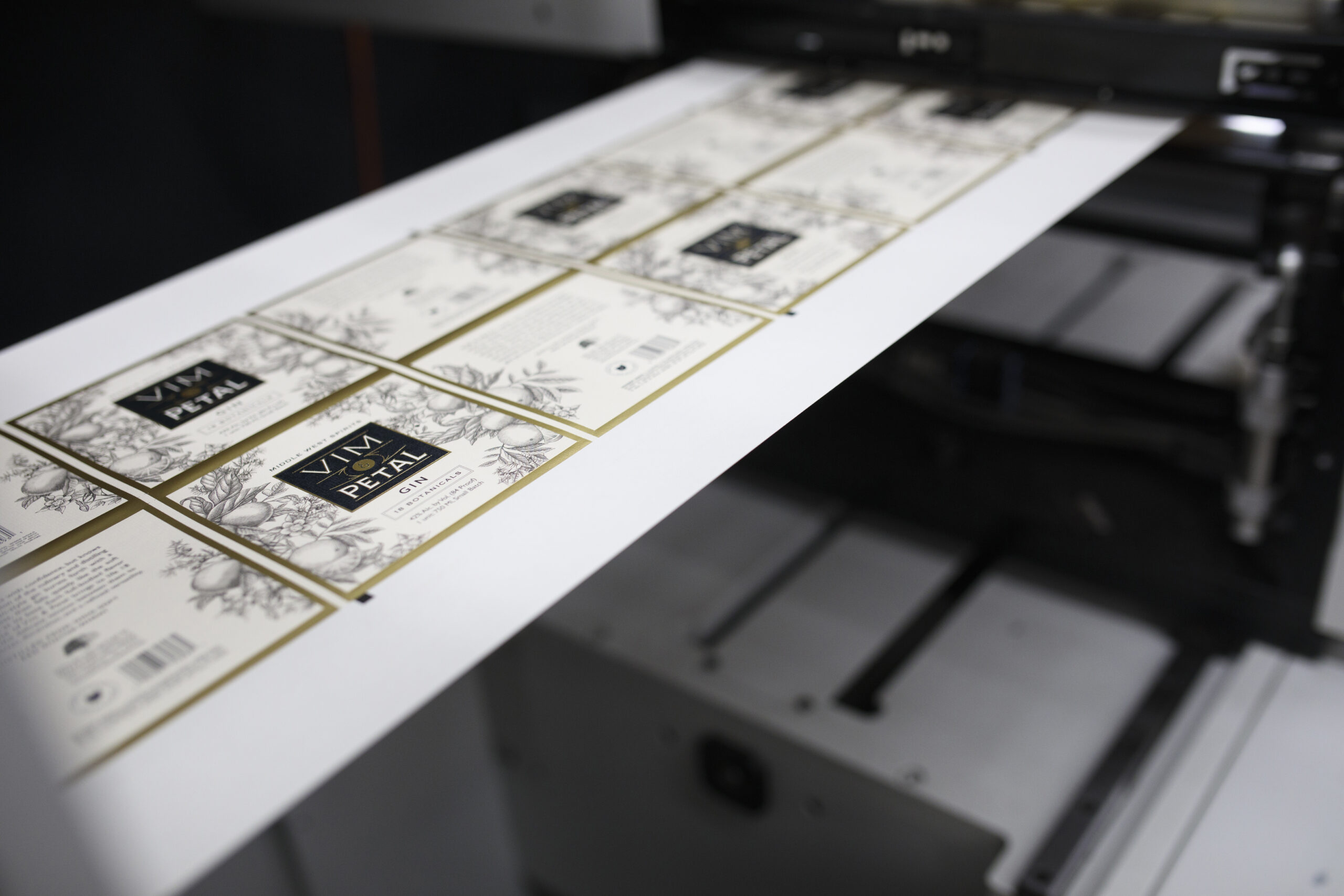

Print Quality

Not everyone gets as excited about the details of printing as we do, so here are some tips to evaluate a label printer based on print capabilities and quality:

- Resolution: The resolution of a printer, measured in dots per inch (DPI), will determine how sharp and clear images and text appear. Higher DPI values produce finer detail, which is essential for labels with intricate designs or small text.

- Color Accuracy: The printer’s ability to accurately reproduce colors is important for maintaining brand consistency. At Blue Label, our HP presses can achieve accurate PANTONE emulations up to 97% using additional HP Indigo Electroinks (orange, violet, and green).

- Print Speed: While not directly affecting label appearance, faster printers can handle larger batches of labels more efficiently.

- Ink Type: The type of ink used by the printer can impact both the quality and durability of the print. For water bottles, it’s important to use inks that are water-resistant and fade-resistant. UV inks and solvent inks are commonly used for their durability and color quality.

- Label Material Compatibility: The printer must be compatible with the specific materials used for your labels, such as vinyl, BOPP, or PET. Different materials may require different types of inks or printing technologies to achieve the best results.

- Finishing Capabilities: At Blue Label, we offer built-in finishing options like lamination, die-cutting for different label shapes, and foil stamping.

- Printer Technology: The type of technology used by the printer affects print quality and suitability for different label types. Blue Label uses digital printing, which offers the highest image quality, a wide range of colors, and the ability to print even small runs at a cost-effective price.

- Software and Integration: The software that accompanies the printer should offer color management tools that allow for precise control over the color of the labels.

Sustainability Considerations

Let’s face it, plastic water bottles are a significant contributor to global waste and pollution. A study in Science Advances reported that only 9% of all plastic ever produced has been recycled, with the rest accumulating in landfills or even the natural environment (including bodies of water).

While you can’t control what consumers ultimately do with your bottle water, you do have options for more eco-friendly and sustainable label options.

- Sustainable Materials: Materials like BOPP or PET are known for their durability but also their recyclability. Beyond these options, there are label materials made from recycled content or even biodegradable.

- Eco-Friendly Inks: Certain water-based and soy-based inks can be eco-friendly choices as they emit fewer VOCs compared to traditional inks.

- Printing Technology: Digital printing technology is generally more eco-friendly than traditional printing methods because it requires less energy, wastes less ink, and eliminates the need for plates and chemicals common in conventional printing methods.

- Removable Labels: Adhesives that allow for easy label removal make the recycling process much easier.

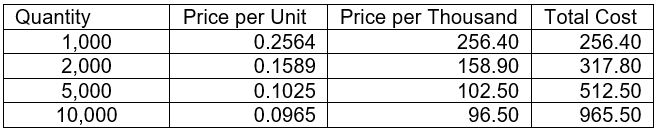

The Cost of Water Bottle Labels

Depending on your product, you may be looking at high-end labels with premium materials and advanced finishing techniques, or you may be considering cost-efficient materials that showcase your brand without fading or peeling.

Here are some factors to consider when evaluating the cost of custom water bottle labels:

- Material Selection: Opting for materials that offer a mix of durability and visual appeal at a reasonable price point can help reduce costs.

- Print Methods: Digital printing eliminates the need for expensive plates and setup costs, making it ideal for both short runs and larger production runs.

- Forecast Needs: Estimate your label requirements accurately to leverage quantity discounts without overstocking.

Get Started

Explore Blue Label Packaging’s label printing options and finishing techniques. Our experts will guide you in selecting the right label face stock, adhesive, and printing method to withstand moisture, temperature changes, and sun exposure. From durable vinyl to flexible film labels, we’ll guide you to the perfect label or sticker for the job.