How to Protect Your Bottle Labels: Laminates vs. Varnishes

- bottle labels

- lamination

- protection

- UV coating

- varnishes

Do I Really Need a Protective Coating for My Bottle Labels?

There is no set rule that you must add a laminate or varnish to your custom bottle labels, but we strongly recommend that you do so. If you choose to go without any protective coating or lamination, you run the risk that something could scratch the ink or moisture could compromise your label, depending on the material of your label.

Without something to protect the ink, any form of friction could damage your design. For example, some distilleries decide against laminates or varnishes because it gives their paper bottle labels a rustic, unfinished look. When those bottles are shipped, they tend to rub up against the cardboard and other bottles. Those attractive labels won’t look nearly as good thanks to scuffs, scratches, and other preventable damage.

There are also other factors that can impact your label. Water and other liquids can wreak havoc on unprotected materials, which is especially problematic for certain bottles. Laminates and UV coatings can also protect ink from the sun and other outdoor elements.

What’s the Best Option to Protect My Bottle Label?

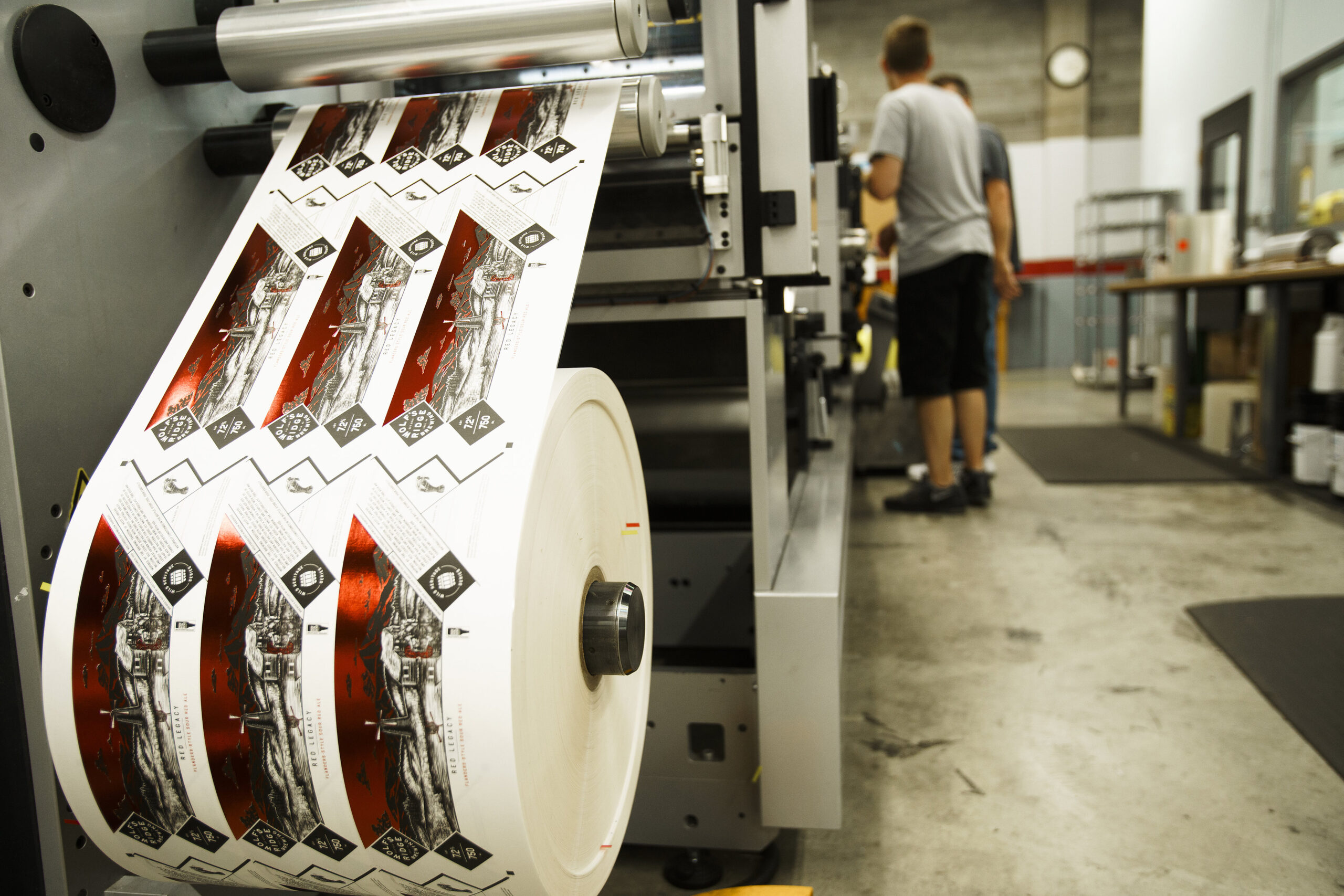

While laminates and varnishes both offer protective capabilities, they have some key differences that may make one a better option than the other for your packaging. In fact, there are ways that you can utilize both laminates and varnishes. The answer to which protective solution is right depends on a few factors.

How much label protection do you need?

Both options will help protect your label, but a laminate offers a greater level of protection than a varnish. A laminate is a separate film that adheres over top of your label, while a varnish is a clear resin that’s applied then cured. This means a laminate allows you to build additional layers of protection instead of reinforcing your existing material, which is good for bottles that may end up in a cooler or other potentially damaging environments.

Do you want to take advantage of decorative effects?

Of the two options, varnish offers you more decorative bang for your buck. There are various types of laminates, such as gloss, semigloss, and matte films, but varnish can help you enhance your design to a greater effect. A spot varnish can apply resin to a very specific part of your label, such as your logo or a specific element of your design to create contrast with the rest of the material. You can even apply a spot varnish on top of a laminate if you want to maximize protection and decoration.

Which label material will you use?

Your label material can play a part in your protection options. If you’re using a synthetic material like a BOPP or plastic-based material, we strongly recommend that you use a laminate. While paper naturally has a grit to it that allows ink to soak into the material, film facestocks are so smooth that the ink lays on top of the material. As a result, the extra layer provided by a laminate is very valuable.

Are there any cost advantages?

The price difference between laminates and varnishes in minimal unless you plan to invest in a large run of labels. In that case, laminates are a bit more cost effective.

Protect Your Custom Labels

Your label can make a good first impression, but an unwanted scuff isn’t going to do you any favors. At Blue Label, we work with you to make sure that your labels a perfect for your needs, both in terms of performance and aesthetic. Contact us today to talk to one of our experts about printing quality, eye-catching labels for your products.