Pick Your Protection: The Different Types of Label Lamination

- aesthetic

- film labels

- lamination

- paper labels

- protection

- waterproof

A good label allows your products to make a great first introduction to potential customers. However, scuffs, scratches, and other forms of damage can mangle your message without protection.

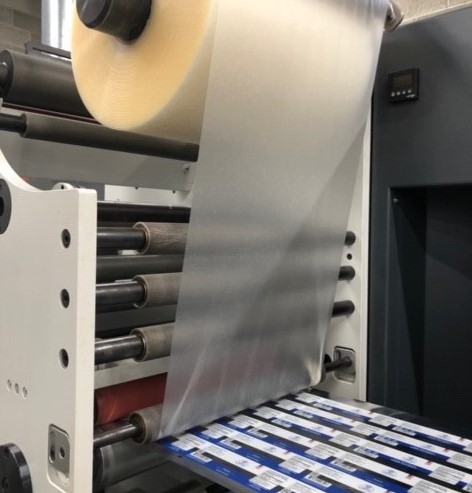

Label lamination allows you to add a protective film to the surface of your label. Once your label is printed, lamination serves as a second skin of sorts that shields your design from scratches and provides some waterproofing for your base material. However, these laminates can offer additional benefits depending on which type of lamination you use.

Breaking Down Each Type of Label Lamination

While laminates in general offer protective capabilities, certain types of lamination can add decorative effects to your label. This variety allows you to pick and choose different label laminates depending on your desired aesthetic. Other laminates can also change the feel of your label or provide certain capabilities not offered by other protection. In general, laminates are broken down into five types.

- Gloss

- Matte

- Soft touch

- Leather

- Thermal transfer

Gloss

If you want your labels to shine, you’re going to like gloss laminates. These laminates reflect light off your label to add a smooth, glossy look that makes your design pop for passing customers.

Matte

If shiny isn’t your thing, a matte laminate creates a more subtle appearance for your labels. A matte finish dulls down your label surface so that it doesn’t shine much at all – but this means your label will be far from dull. These laminates can create a soft, subtle look that allows certain elements and colors appear deeper and brighter in contrast to the matte finish.

Soft touch

While matte finishes can make your labels look soft to the touch, other laminates can create a velvet-like, matte finish. Soft touch laminates add a tactile quality to your labels that consumers can feel. Research shows that the feel of a product can help sway buyers, which means that soft touch laminates can be a difference maker if you want that velvety aesthetic.

Leather

If you like the rugged, textured look of a paper label material but want the performance capabilities of a film, leather laminates help you achieve the best of both worlds. Leather laminates allow you to recreate weathered, wrinkled effect on film labels. This type of laminate works best on dark colors that allow you to highlight the texture of your label, all without the fuss of having to flood paper labels with ink or deal with potential durability issues.

Thermal transfer

Unlike other types of laminates, thermal transfer finishes are chosen more for what you plan to print on your labels in the future. These laminates allow you to use thermal printers to print on top of your labels whereas other lamination may prevent the ink from sticking. For example, a deli with a branded label may want to print the weight and price for each order on its labels. Thermal transfer laminates allow these types of businesses to do so, all while adding a gloss, matte, or some other type of look to their labels.

Invest in the Right Protective Film for Your Labels

Product labels come in so many different styles. No matter which aesthetic you prefer, it’s important to protect your label design from harm. To do so, you’ll need to figure out which form of protective film is best for your needs, whether it’s a laminate or some other option.

Label laminates typically adhere to film material better than paper, while varnishes conform to the nooks and crannies that can be found in paper materials. You can also add a varnish on top of a label laminate to really make certain design elements pop. There are so many possibilities to amp up your design and protect your label that it can be a bit overwhelming without some guidance.

Fortunately, a good lamination packaging company can help you weigh your options. At Blue Label, we work with you to identify the right details for your design, including label material selection and protection. Contact us today to invest in the right labels for your business.