Protect your Label: The Different Types of Label Varnishes

- aesthetic

- film labels

- paper labels

- protection

- varnishes

As with lamination, there are multiple label varnishes available to not only help you protect your label as well as enhance your design. Each type of varnish can help you defend your label from scuffs, scratches, water damage, fading, and other threats, all while contributing to your preferred aesthetic.

Breaking Down Each Type of Label Varnish

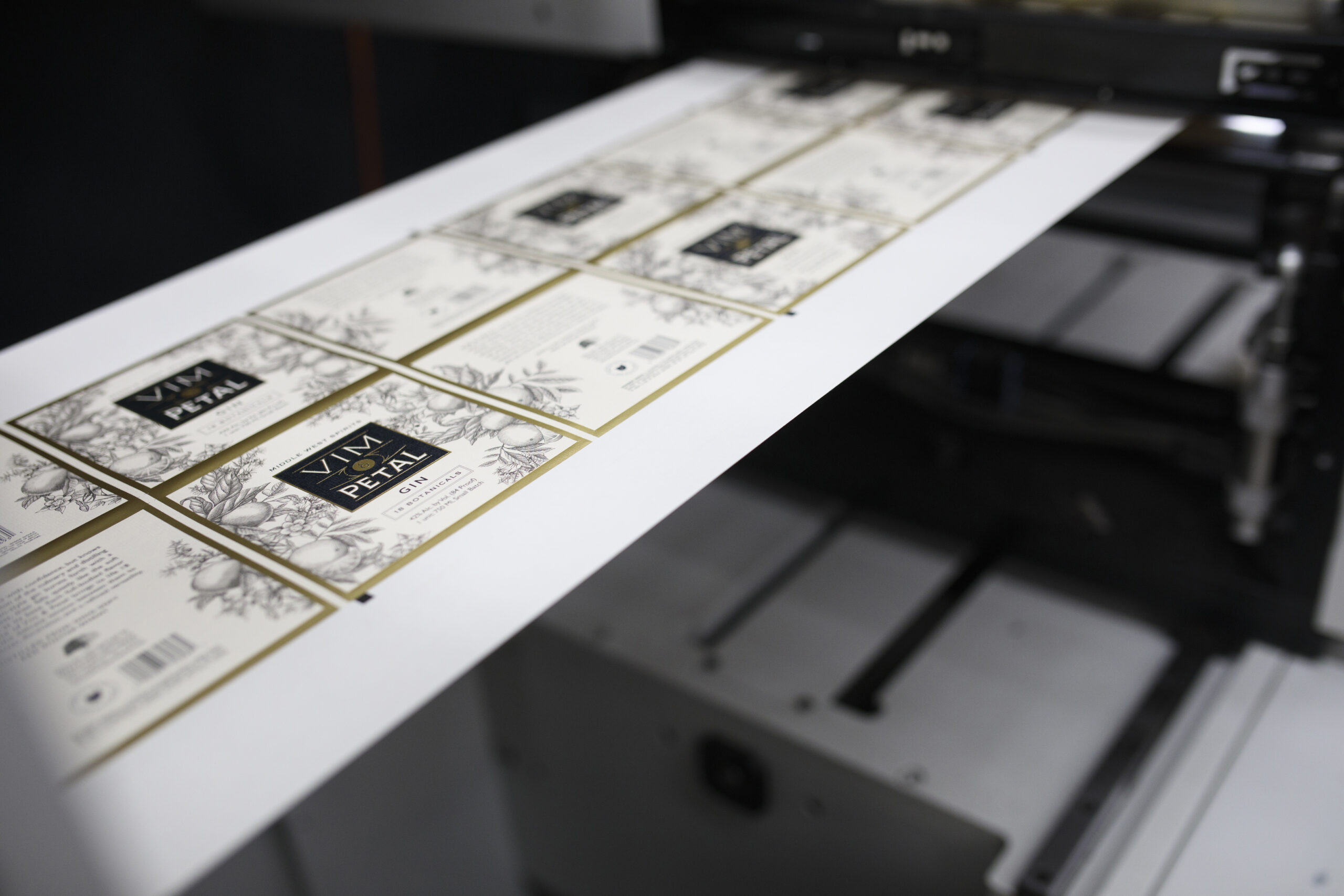

While label lamination utilizes a layer of film to protect your label, varnishes operate a bit differently. Label varnishes are liquids that are rolled onto a label and then cured or dried so that the varnish adheres to the label materials’s surface. This method makes varnishes a good option for paper labels because the liquid can conform to the texture of the paper and fill in any nooks and crannies.

Like laminates, there are a few different types of label varnishes that differ based on the application process or their final appearance.

- UV coating

- Aqueous coatings

- Gloss, satin, and soft-touch varnishes

UV coating

As the name suggests, UV coatings use ultraviolet light to cure a liquid coating made of a special mix of chemicals. Once it’s cured, the UV varnish essentially bakes onto your label material to create a protective coating. This newly cured shield basically acts as a permanent sunscreen, preventing your design from fading over time and other factors that can damage your label.

Aqueous coating

Like a UV coating, aqueous coatings use a special solution to protect your label. However, you don’t need UV light to cure aqueous varnishes. These solutions are a clear, water-based varnish that quickly air dry to seal off your label materials from potential danger.

Gloss, satin, and soft-touch varnishes

While UV and aqueous coatings differ in terms of the process used to cure them, gloss, sating, and soft-touch varnishes denote the finishing effect a coating has on your label. Gloss varnishes create a smooth, shiny look for your labels once applied. Satin varnishes – known as “matte” for laminates – cut out most of the shine to create a flat look that makes other design elements pop. Soft-touch varnishes not only look soft, they can even add a soft textural element to your labels as well.

Protect and Enhance Your Labels with the Right Varnishes

No matter what type of product you sell, it’s well worth the investment to protect your labels. Scuffs and scrapes can happen to any product label, and once that ink comes off your label there’s not much you can do. Varnishes and laminates offer both protection and aesthetic improvements – it’s just a matter of finding the right one for your needs.

Fortunately, you don’t need to find and apply your own varnishes. At Blue Label, we can guide you through every step of the label process, including applying varnishes or laminates to protect and enhance your designs. In fact, we can even add a varnish on top of a laminate to highlight specific design elements. Every label is different, so we work with you to figure out the best ways to showcase your products.

Ready to invest in eye-catching labels built for success? Contact us today about printing your next batch of product labels.