A Guide to Label Durability: Materials, Environments, and Best Practices

Label durability is one of the most important aspects of product packaging. It can influence the label’s functionality and your brand’s overall perception. A weak and flimsy label can make the product look weak and flimsy, too.

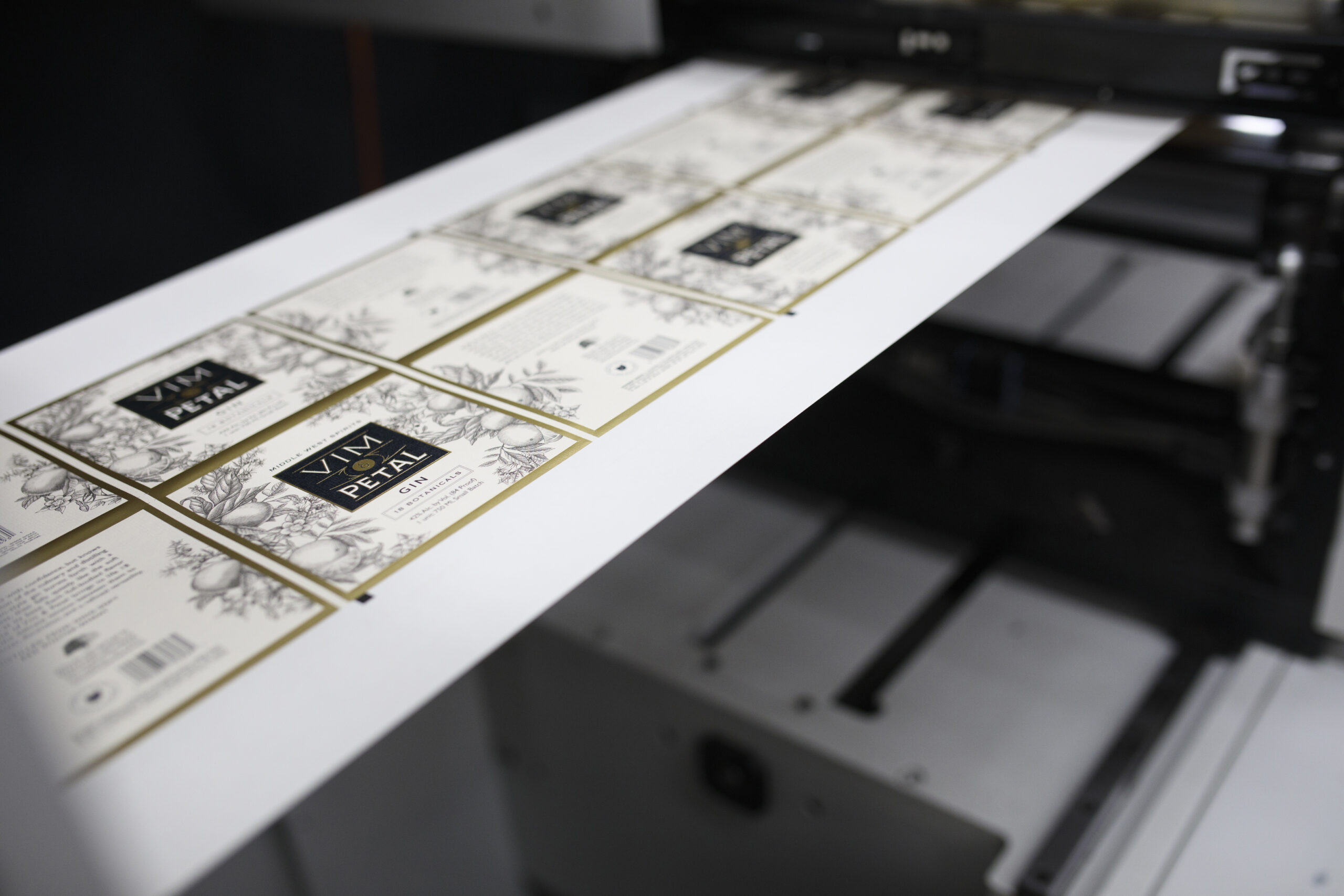

Durable labels do more than just resist wear and tear. Choosing the wrong material, adhesive, finish, or even application technique can lead to one of the many stories we’ve heard of labels peeling, tearing, fading, and falling off (like the product below).

But don’t worry, we’ll guide you through making the right choices so your product shows up and stays looking its best.

4 Environmental Factors Impacting Label Durability

It can be rough for a product going in and out of production lines, packing, stocking, and, eventually, your customer’s home. It’s important to consider that you not only want your product to show up gleaming on a shelf or your customer’s doorstep, but you also want a resilient label that lasts.

Understanding how environmental factors affect durability will help you create an ideal label. Let’s start by looking at the four big environmental considerations: moisture and humidity, temperature, UV exposure, and abrasion resistance.

1. Moisture and Humidity

The Challenge

Moisture can be the end of a perfectly good label design, whether from the product itself or surrounding environments that your products might find themselves in, like bathrooms, kitchens, or outdoor settings.

Moist conditions can lead to adhesives failing, ‘label swelling,’ or degradation of the print on the label. The worst case scenario: compromised product integrity and brand reputation. But moisture-resistant labels can help.

Recommended Materials

- BOPP (Biaxially Oriented Polypropylene) is highly resistant to moisture, making it ideal for products exposed to moist environments.

- Vinyl is water-resistant and durable. It’s best suited for products that are frequently exposed to water or stored in humid conditions.

- Polyester labels are moisture-resistant and excellent for indoor and outdoor use.

Additional Printing and Finishing Techniques

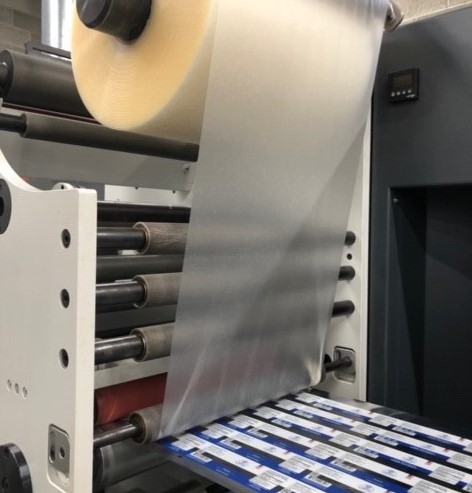

- Lamination adds a clear laminate over a label that creates a barrier. This adds a step to protect the printed design and ensure the label remains intact even in wet environments.

- UV coating, while primarily used for protection from UV light, adds a layer of resistance, helping to seal the label’s surface.

Adhesives

If you’re worried about peeling, water-resistant adhesives are the way to go. These types of adhesives are specifically designed to maintain their bond even in the highest moisture environments. This prevents the label from peeling or losing “stick” when exposed to water or humidity.

2. Temperature Fluctuations

The Challenge

Extreme heat, cold, and even rapid temperature changes can compromise your label’s integrity. Conditions like this can lead to adhesive breakdown, label deformation, or fading of printed information. All of this can ultimately affect product presentation and degrade consumer trust.

Shipping through the summer? Heat-resistant labels can be a good solution.

Recommended Materials

- Polyester (PET) labels are exceptional for both high- and low-temperature environments. This makes them suitable for products that are stored across environments — refrigerated, frozen, or stored in warm places.

- Polypropylene (PP) labels are highly resistant to temperature variations. They are commonly used for products that move between cold storage and ambient shelves, like certain beverages.

- Vinyl tolerates temperature extremes well. It’s a solid choice for outdoor products or SKUs that undergo pasteurization.

Additional Printing and Finishing Techniques

Heat-resistant inks are designed to withstand high temperatures without fading or altering. This ensures the label remains legible and intact. Cold-resistant adhesives perform well in low temperatures and can prevent labels from peeling or becoming brittle when exposed to cooler environments.

Adhesives

Sometimes, you have to be prepared for all situations, from extreme freeze to hot and humid. Fortunately, there is an adhesive solution that lends itself to both ends of the temperature spectrum. Temperature-resistant adhesives are designed to remain consistent across temperature ranges, ensuring that the label stays adhered to, hot or cold.

Freezer-grade adhesives are also an option for products that may spend extended amounts of time in below-freezing environments.

3. UV Exposure

The Challenge

Ultraviolet (UV) exposure can pose a number of risks to your label. It can cause fading, material degradation, loss of print legibility, and make bar codes unreadable. Products displayed on bright or sunny shelves or those exposed to sunlight in any part of the supply chain are particularly vulnerable.

Recommended Materials

- UV-coated paper will go a long way in protecting your label. It is a specially treated paper, treated with a glossy coat and cured using special equipment to add a layer of protection.

- Polyester (PET) is naturally resistant to UV light. It’s a great choice for outdoor products.

- BOPP with UV Inhibitors, also known as BOPP UV Resistant, has a film that protects against solar exposure.

Additional Printing and Finishing Techniques

- UV varnishes applied to a label’s surface add protection against fading and discoloration.

- Fade-resistant inks are designed to keep colors vibrant over time, regardless of UV exposure.

- Overlamination with UV Protection includes UV inhibitors using a solvent acrylic adhesive.

Adhesives

There’s an adhesive for every environmental problem! UV-resistant adhesives don’t yellow under UV exposure and have no surface tack at room temperatures.

The other option is acrylic-based adhesives — one of the only options that is inherently UV resistant. Acrylic adhesives are known to keep their bond strength even under UV light exposure.

4. Abrasion

The Challenge

Whether we like it or not, products may see some wear and tear in the supply chain and under regular consumer use. Wear or abrasion during shipping and handling can affect the appearance and functionality of products before they even get to a shelf.

Worn-off instructions or barcodes can cause significant problems. Fortunately, these issues can be mitigated with the strategic use of durable materials and consideration toward finishes.

Recommended Materials

- Vinyl is a tough material that gives excellent resistance to tearing and abrasion.

- Polyester (PET) is durable, resistant to wear, and offers great abrasion resistance.

- Polyethylene (PE) is flexible and resistant to impact. This makes it ideal for products that might be squeezed during handling, like cosmetics, kitchen, and bathroom products.

Additional Printing and Finishing Techniques

- Scratch-resistant coating gives an extra layer of protection against scuffs from rubbing or abrasion.

- Durable laminates with added thickness, like polypropylene (PP), can add an extra layer of protection against physical damage.

Adhesives

Pressure-sensitive adhesives with abrasive grit provide a strong initial tack that will hold and not shift under the rigors of transportation. This will ensure that labels stay on, even under stress.

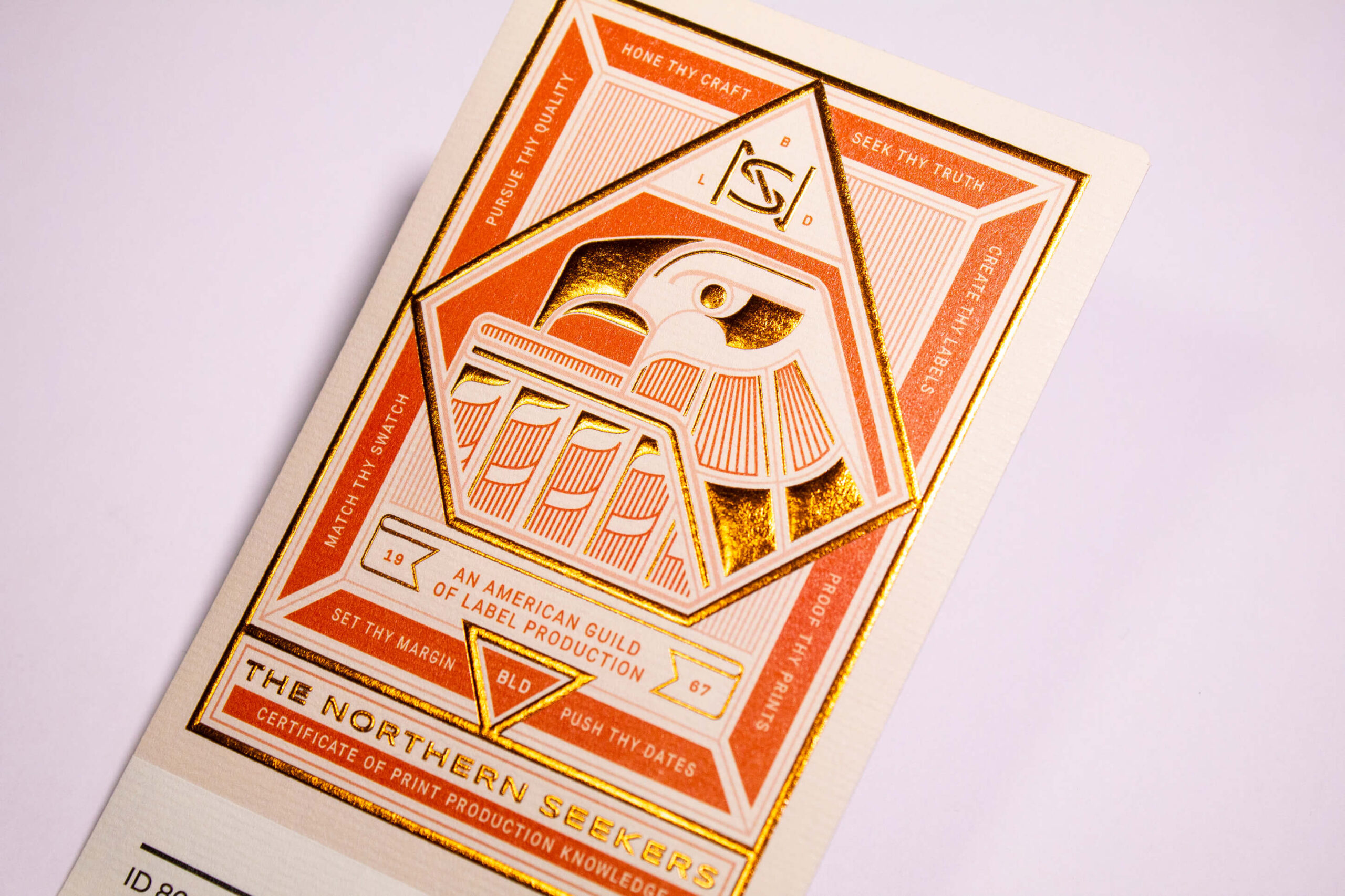

Label Varnishes

Like different kinds of lamination, there are a few varieties of label varnishes also available to protect your label and even enhance your design. Varnishes are a great finishing technique that helps defend against scuffs, scratches, water damage, and fading while giving better overall longevity.

Common options include:

- Gloss varnish

- Matte varnish

- Soft-touch or textured finishes

Label Application Considerations

Curing Time

Give it time—it’s important to allow sufficient time for your label’s adhesive to fully bond before exposing the product to extreme environmental conditions — especially extreme heat. Following the recommended curing times will result in maximum adhesion strength.

Typically, manufacturers recommend a curing period ranging from 24 to 72 hours, depending on the type of adhesive used and the environmental factors involved.

Apply in a Controlled Environment

Applying labels in a controlled environment where temperature and humidity are kept within recommended ranges can significantly aid the curing process. This ensures that labels perform reliably throughout their intended lifespan.

Get Durable Labels for your Products

Ready to invest in eye-catching, durable product labels? Contact us today to check out our materials, get a sample pack, or request a quote.