Kiss Cut vs Die Cut Labels: Understanding the Difference

If you’re looking for cutout labels for your product packaging, you may have come across two common types: kiss cut and die cut.

While both of these labels may look the same on the surface, they differ in a few ways, including the way they’re cut, how they’re applied, and the process of producing them.

Because of their distinctive shapes and designs, both types of labels can be used for packaging that requires a more intricate cutout design.

In this article we’ll explore kiss cut vs die cut labels by digging into their differences and similarities.

What Are Kiss Cut and Die Cut labels?

If you’re looking for a label that allows you to showcase an intricate design, these are generally the two cutting techniques that are available. Understanding them can help you get what you’re looking for.

Kiss Cut labels

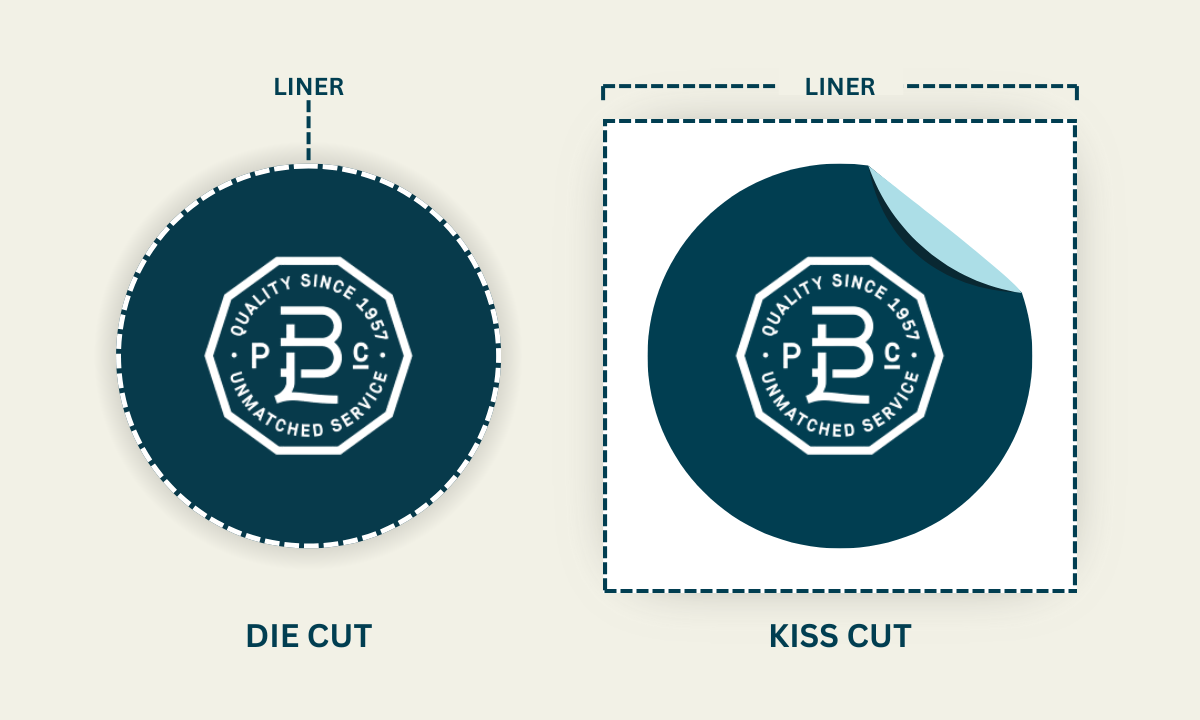

Kiss cut labels are only cut through the vinyl layer while leaving their paper backing intact.

These labels are printed on a vinyl sheet, then a cutting machine is used to cut through the vinyl paper while leaving the adhesive intact. A professional printer will adjust settings related to pressure, speed, and cutting depth. The result is a kiss cut sticker is easy to peel and apply on your desired surface.

Kiss cut labels are generally durable, and the intact backing helps protect the labels until they are ready to be used.

Die Cut labels

Unlike kiss cut labels, die cut labels are cut completely through both the vinyl layer and the backing material. This keeps the sticker in its exact shape without any extra material on the sides.

Die cut labels are created by printing the design on vinyl and using a die (a tool, often made from metal) to cut through the backing paper and vinyl. The outcome is a custom-shaped sticker without any excess material.

Die cut labels tend to be a bit more durable and resistant to the elements than kiss cut labels, making them a more suitable choice for outdoor use, rough handling, or products that encounter changing environments.

Specific Applications and Suitability

Kiss cut or die cut labels can be used to complement existing packaging or labeling, and other times the product label itself is a kiss cut or die cut shape.

Food and Beverage Products

From craft beers to specialty foods, these labels can complement existing packaging design or become the focal point of the product itself. Here are some examples:

- Standard cutout product labels including branding, product name, ingredients, nutritional information, and more

- Custom-shaped labels that match the shape of the product or the shape of the label design itself, providing a unique and eye-catching appearance

- Product identification labels for different flavors or batches, making it easy for consumers to distinguish between choices

- Promotional labels for temporary promotions, limited-time flavors, or part of a promotional marketing campaign

- Decorative designs for limited-edition products and seasonal themes like holidays

Health and Beauty Products

For health and beauty products, kiss cut or die cut labels can help with unique product packaging shapes, but also help fit additional design or informational elements when space is precious. Here are some examples:

- Labels with product information including ingredients, branding, and product name

- Uniquely shaped labels and labels for products like perfumes, serums, and other specialty healthy and beauty products

- Product differentiation labels to showcase different scents, colors, or formulations of products

- Decorative elements on a sticker or label, including metallic foil or embossed elements, to enhance the visual appeal of the existing packaging

Home Goods

Looking for cutout labels or labels for a home goods product? In that case, consider kiss cut or die cut labels for:

- Uniquely shaped labels for non-standard packaging for products like decorative items, candles, cleaning supplies, and more

- Production differentiation labels to showcase different scents, colors, or features of similar products

- Feature or callout labels for everything from a “new and improved” formula to competitor claims like “twice the cleaning power”

- Safety warnings to display precautions and ensure the safe use of products

Differences Between Kiss Cut and Die Cut labels

Here are some common differences between kiss cut and die cut labels:

Cutting Method

As you now know, kiss cut labels only have their top vinyl layer cut while leaving the paper backing untouched. On the other hand, die cut labels are cut completely through the paper backing.

Size And Amount

Kiss cut labels are available in the form of label sheets and single pieces. Meanwhile, the sizes of die cut labels may vary according to the design.

Shape Option

The shape of both labels or labels depends on your design. Kiss cut labels may have some practical limitations once you get into highly complex designs. Likewise, the cost die cut labels may increase as the complexity of the shape increases.

Production Speed

Kiss cut labels are produced faster due to the fact that the process doesn’t involve cutting the backing paper. Meanwhile, die cut labels take slightly longer to produce as the sheet is cut into precise custom shapes.

Waterproof Qualities

Since both labels can be made with vinyl, they can accommodate environments that will encounter humidity or moisture.

Application

Kiss cut labels are convenient to peel with an easy backing paper. Die cut labels must be individually peeled off their own backing piece, but the precise cut ensures that the edges are clean, making them easy to peel without tearing.

Durability and Quality

The extra backing helps give kiss cut labels added durability before application. The durability of both of these labels will be similar and will depend more so on the materials used.

Surface Support

Both types can adhere well to flat and slightly curved surfaces, but die cut labels may face challenges on highly textured or irregular surfaces due to their precise shapes.

Price

Since kiss cut labels require a less complicated procedure, they tend to be more affordable. On the other hand, die cut labels tend to cost more due to their intricate details and the cost of machining and custom dies.

What Material Is Used for Kiss Cut and Die Cut labels?

Luckily, with either cutout type, you can get your labels made using a wide variety of materials. Vinyl, paper, and polyester are common materials used for both kiss cut and die cut labels.

Additionally, you can opt for eco-friendly options if you solely care for the environment. For instance:

- Consider using recycled paper for your label or sticker material

- Biodegradable vinyl is also a good option as it breaks down on its own with time

- Labels can also be made using plant-based materials like cornstarch and bamboo

You can go one step further and use soy-based inks and water-based adhesives for a more environmentally-friendly production process.

That said, you should be aware of certain limitations with eco-friendly materials. For instance, they are much more costly than common materials. They also may have limited durability and their performance may also not be as good as traditional materials.

Pros and Cons of Kiss Cut and Die Cut labels

To help you decide, here’s a list of pros and cons for each option:

Kiss Cut Labels: Pros and Cons

| Pros | Cons |

|

|

Die Cut Labels: Pros and Cons

| Pros | Cons |

|

|

Application and Removal of These Labels

Both kiss cut and die cut labels can be made with permanent or removable adhesives.

Removable adhesives are temporary adhesives that remove labels without leaving any residue on the surface. They are perfect for temporary or promotional labels.

On the other hand, a permanent adhesive provides a solid bond that helps your sticker stay adhered to the surface for a long time. This type of adhesive best suits product label labels or permanent branding.

Design Considerations for Kiss Cut and Die Cut labels

Whether you opt for kiss cut or die cut labels or labels, here are a few design best practices to consider:

Kiss Cut Labels

- Define an outline in the sticker design to ensure accuracy during the cutting and printing stages

- Indicate a safe zone within the outline with important design elements to prevent them from getting cut out

- Create a border around the outline to ensure neatness

Die Cut labels

- Create a bleed area that extends beyond the die cut outline to avoid any white edges from showing

- Add radius to shapes with sharp corners as it saves sticker corners from tearing during peeling

- Maintain a safe zone with all the crucial design elements to prevent them from getting cut out

Next Steps

You can learn more about all of the finishing options that Blue Label offers for product labels. No matter your product or intricacy of your artwork, we can help you identify the right cutting process, materials, and finishes and for your label’s exact shape.