The Different Wine Label Stocks You Can Use to Showcase Your Bottles

⚞ The Highlights:

- Common wine label stocks include textured papers for a premium look, uncoated or coated papers for versatility, and synthetic or film materials for added durability and moisture resistance.

- Paper stocks, including estate paper, are popular for wine labels because they provide a premium, textured appearance, absorb ink well for a rich look, and give an artisanal touch.

- Other label materials, such as synthetic or film options, offer greater durability and moisture resistance, while metallic foils or clear films can provide a premium sheen or transparent look.

When it comes to investing in wine labels, it’s good to have options. There are a variety of label materials to choose from, but it’s up to you, your designer, and your label printing company to decide which one makes the most sense for your bottles. When it comes to wine labels, the three most popular types of materials you can use are:

- Estate

- Ever-opaque

- Specialty

Each category offers various advantages depending on your desired look, feel, and price point. Here’s a quick breakdown of the different types of wine stocks so you can figure out what’s right for your packaging needs.

Estate Wine Labels

When you think of a classic paper wine label, you’ll likely envision something made with an estate material. Estate materials are a popular choice for the wine industry, and for good reason – they have a classic look and are generally a more cost-effective option.

Another advantage of paper labels is that they are incredibly versatile. While paper typically exudes a very natural appearance, there are various types of paper materials that can either enhance that look or provide a new type of aesthetic. For example, linen-style or uncoated eggshell bottle label papers both have different textures in the paper fibers that can help you match the look you want for your wine labels.

Of course, there is a downside to using an estate material. Unlike film, wine label paper absorbs water, which can cause those labels to disintegrate over time. While there are some paper stocks that have a higher wet strength, even those options aren’t completely waterproof. As such, estate may not be the best option if your wine labels will encounter water.

Ever-Opaque Wine Labels

If you really love the look of estate but are concerned about water damage, you should consider investing in an ever-opaque material.

Ever opaque wine labels have a layer of BOPP film woven between paper to help shield your labels from moisture. This material option allows you to still give your bottles an estate feel without the downsides of soggy paper wine labels. This can make ever opaque materials a go-to option for white wines that are typically chilled before use or any other bottles that may encounter moisture throughout its journey from your facility to your consumers’ tables.

As can be expected, the downside of ever-opaque stocks is that the presence of a BOPP film can drive up costs. However, that increase may be well worth the investment if it protects your labels from future damage.

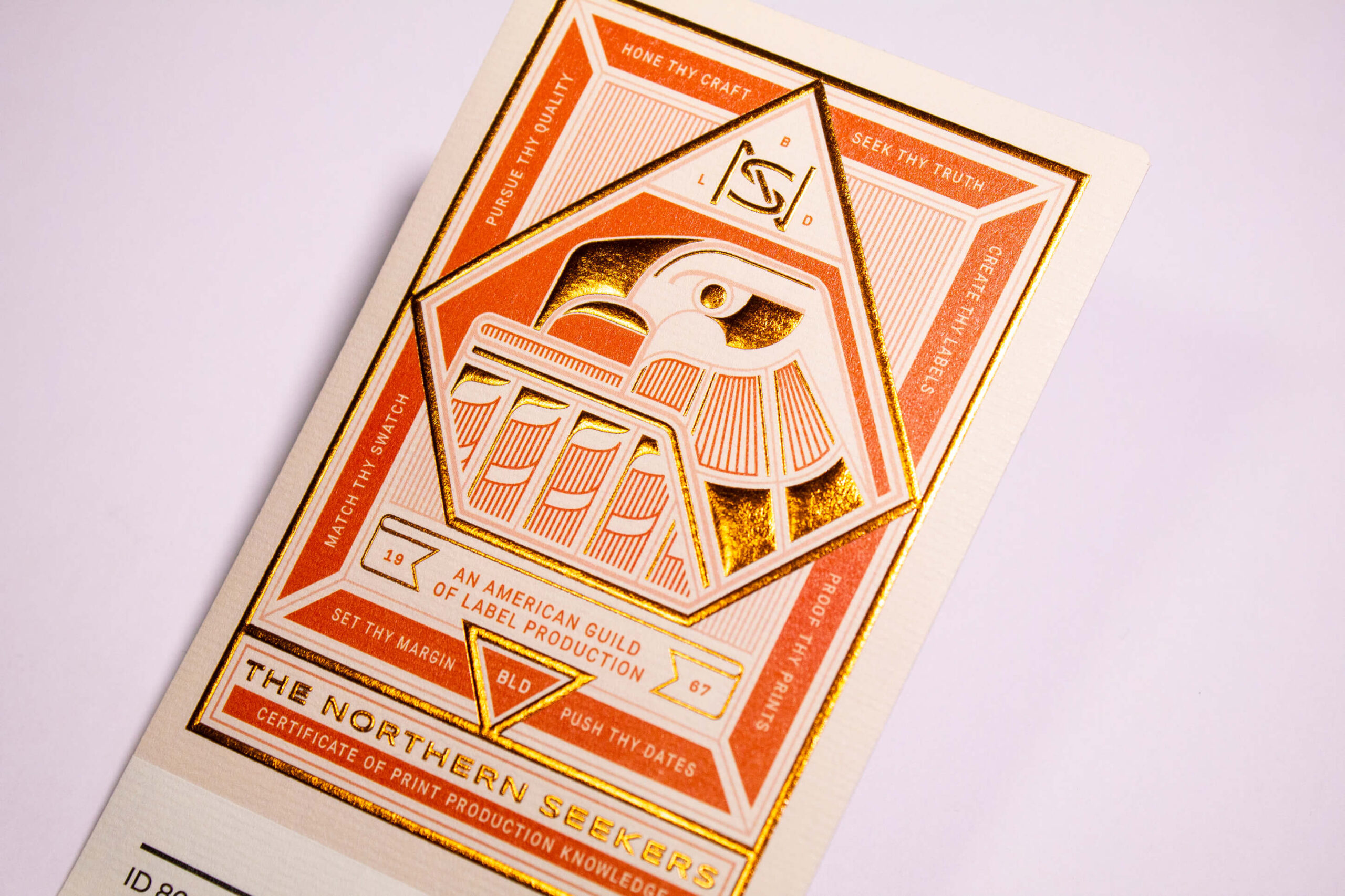

Specialty Wine Labels

While both estate and ever-opaque wine labels have a more traditional look and feel, specialty label stocks can help you take your bottles to a whole new level. These can be made of paper or film and vary greatly in terms of overall aesthetic. Some specialty options include:

- Felt/velvet materials

- Cobblestone patterns

- Shrink sleeves

- Holographic or glitter films

- Gloss, matte, satin, and soft-touch varnishes or laminates

As you can see, there are plenty of possibilities to break out of the classic wine label mold with specialty labels. The various materials available will each have their own distinct advantages, but when used properly, they can make sure that your bottles stand out when placed next to your competition.

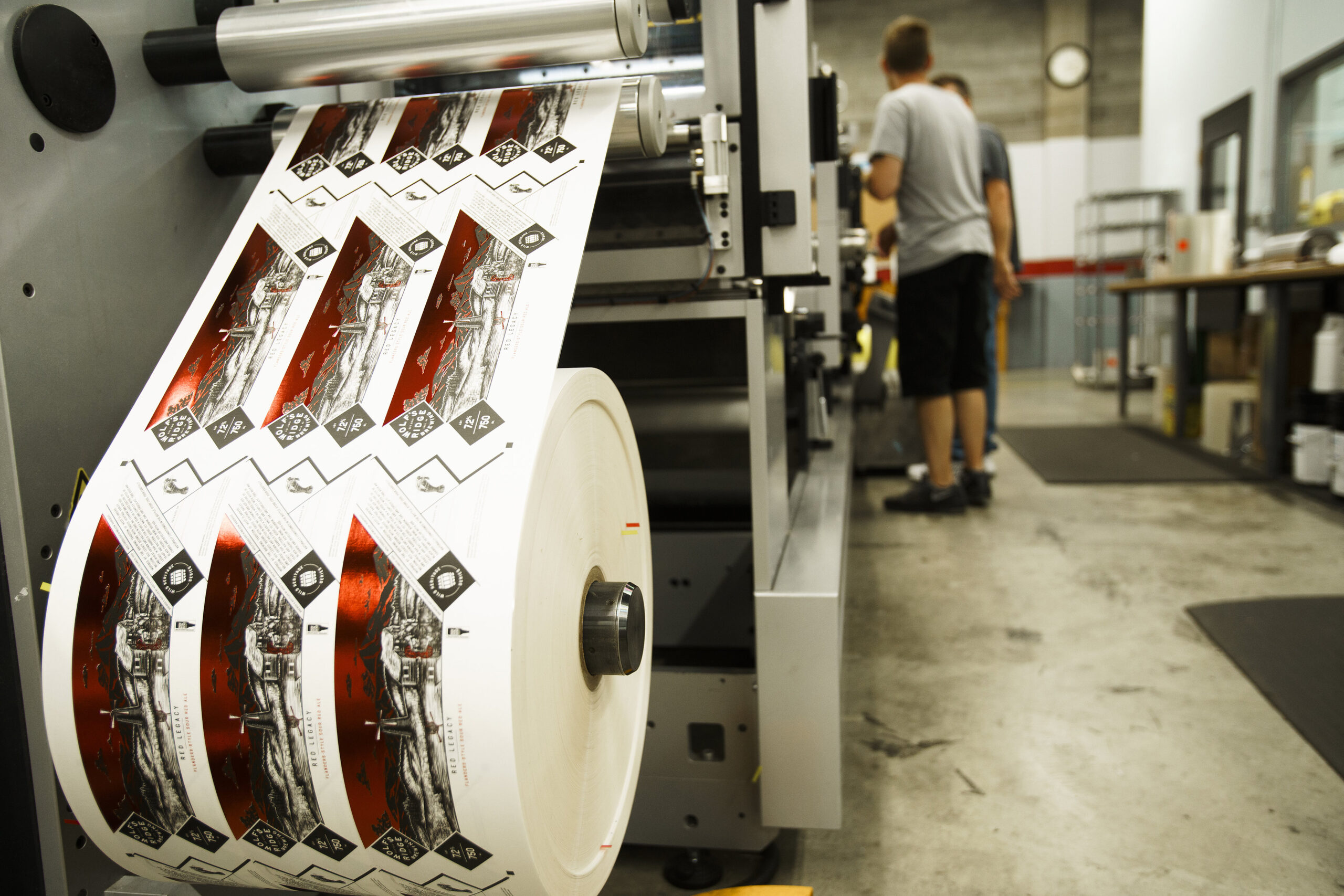

Work with a Label Printing Company that Makes Your Wine Labels Shine

No matter which wine material you like best, it’s important that you partner with a printing company that can turn your design into stunning, eye-catching labels. At Blue Label Packaging Company, we have the expertise and state-of-the-art printing equipment necessary to print stunning labels at competitive prices. We work with you to identify the right label material for your needs, and we can provide special label printing and finishing capabilities to add an extra dimension to your label design.

Are you in need of top-quality wine labels? Contact Blue Label today to talk to our experts about your next label printing project.