A Comprehensive Guide to Clear and Transparent Product Labels

Sometimes a see-through label is the perfect way to make sure people notice your products. Clear and transparent product labels create a striking look that emphasizes your container – and potentially everything inside of it. When done right, see-through or transparent labels can give alcohol, beauty products, and other types of packaging a clear advantage over the competition.

Of course, the key phrase here is “when done right.” There are some issues that can occur without proper planning. However, planning ahead for these factors can help you attain a stunning look for your labels. Here are some things to consider when investing in a clear or transparent label.

Why Clear and Transparent Labels

Clear packaging and transparent product labels are piquing the interest of brands seeking to elevate their product’s appeal. Consumers are also drawn to transparent labels as they give products sleek, modern styling and allow you to see the contents inside.

Which Products Are Best Suited for Clear and Transparent Labels?

Clear and transparent labels allow certain products to highlight visual aspects that appeal to buyers:

- Beverages – Clear bottles and labels showcase juice pulp, fruit, and appealing liquid colors.

- Foods – Seeing ingredients like jams, sauces, and frozen fruits maintains their fresh aesthetic and communicates homemade appeal.

- Health/beauty – Showcasing product colors, shimmer, or even skin tone matching helps drive interest and purchases.

Compatibility with Different Containers and Materials

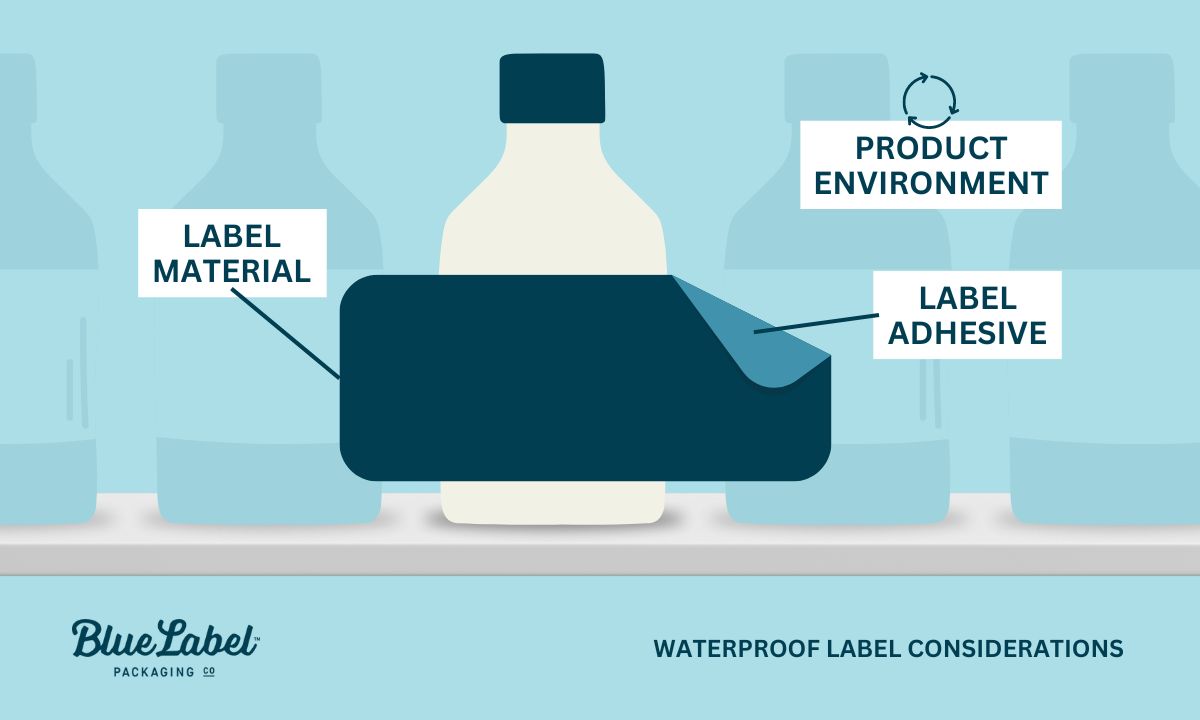

If you want clear or transparent labels, you’ll need to use some type of film material, such as a BOPP – after all, there is no see-through paper label material. Since you’ll need a film, you’ll also want to add a laminate or varnish to protect your label from scratches and other damage. In terms of what type of film is best, it largely depends on your container.

Identifying the right clear label material really comes down to what your container is meant to do. If you need a label for a squeeze bottle, you’ll want a material like MDO that’s meant for flexible containers. More rigid containers like glass bottles may lead you to crystal clear films so that you can showcase your product, such as labels for spirits and other higher-end products. These details can help a label printing company identify which material is best for your specific situation.

Design and Color Considerations

While transparent labels offer creative potential, they also come with unique design considerations compared to other label types and materials. Knowing how to design for clear labels is important—here are some tips:

Color Considerations

Label colors will blend with any visible background hue from bottles or contents behind them. For example, red label graphics on a blue bottle will shift purplish. To control for this:

- Put white ink layers behind label design elements to blank out backgrounds. Multiple layers may be required to fully block out bold container colors.

- Test print label proofs applied to sample bottles and contents to preview results of transparent inks blending with visible hues. Adjust colors accordingly.

At Blue Label, we can generate physical label samples for testing on the actual containers. Proofs provide visibility on exactly how custom graphics and chosen colors will render prior to final printing approval and full purchase. Leverage proofs to lock in ideal transparent label results.

Size and Shape Considerations

Clear label materials open up a new world of options for packaging designs compared to paper labels. Consider unique sizing and die cuts to maximize visibility and shelf appeal.

- Non-Standard Dimensions – Move beyond standard label sizes to precisely fit the exact contour of any bottle, jar or container shape. Height, width, corners and more can all be customized.

- Rounded Corners – Softly rounded or dramatically shaped label corners complement curved containers like wine bottles or cosmetic jars.

- Die Cut Shapes – Laser die cutting creates labels shaped like logos or abstract art forms.

- Placement – Unconventional label dimensions or transparent cut-outs enable brands to feature multiple interactive front, back, side and neck labels for expanded real estate to showcase ingredients and tamper-evident seals.

Overcoming Challenges

- Dark bottle colors can restrict label artwork shades visible through the reverse side. Accentuate with colors optimized for contrast.

- Details can get lost on shiny materials. Employ techniques like patterns, outlines, and pronounced fonts.

Telling Your Brand Story

With thoughtful design, transparent labels artfully showcase what’s inside a bottle or container while allowing complimentary creative embellishments:

- Feature appetizing food close-ups “suspended” in clear jars or containers.

- Use vibrant label colors and graphics to play up appetizing liquid hues visible through clear bottles. White ink pops!

- Print artistic patterns, abstract shapes or product sketches directly onto see-through materials.

A reputable label printer can provide guidance to overcome aesthetic hurdles while unlocking innovative ways clear labels enhance presentation.

Cost Considerations

While visually striking, transparent label materials and specialized printing can carry higher costs than other label materials. Consider these factors:

Label Material Differences

Common transparent label materials:

- BOPP (Biaxially-oriented polypropylene) – Glossy polymer film adaptable for complex shapes.

- PET (Polyethylene terephthalate) – Crystal clear polyester often used for health/beauty.

- HDPE (High-density polyethylene)- Strong moisture-resistant film.

These plastic films generally cost 10-30% more than paper label materials of the same size, but they enable 360° visibility of contents.

Printing Differences

Precision registration (lining up) of multi-color transparent label graphics also demands specialized printers and operator expertise. Metallic inks, custom mixing for passthrough hues, and other special embellishments increase print complexity and associated setup and per label expenses.

Evaluating ROI

While the upfront material and printing costs may be slightly higher, the return from product differentiation, consumer engagement, and sales gains over time can offset those costs. Conduct pilot studies across different products to measure the impact that different labels and packaging options have on ROI.

Preparing Artwork Files for Clear or Transparent Labels

When providing label artwork files for printing transparent labels, ensure:

Proper File Setup

- Supply artwork as print-ready PDFs or high resolution PSD/AI files so see-through elements render precisely.

- Review files at 100% scale and max quality to validate designs before submitting.

- Activate transparency flattening settings when saving PDFs to properly blend artwork layers.

- Understand acceptable file formats and ensure your printer performs a design file review before sending your label to print.

Design Considerations

- Use white ink layers behind designs or apply white label backings so bottle colors don’t alter graphics.

- Embed or link all fonts and images. Supply high-res photos scaled 1:1 for best clarity.

- Request test prints applied on sample containers filled with product substitutes to preview final transparent labeling results.

Submitting flawless artwork with visibility-enhancing techniques delivers superior transparent label outcomes that make products shine.

Label Placement and Application

Transparent labels readily showcase any labeled surface imperfections like the following:

- Air bubbles beneath labels become clearly visible.

- Fingerprint smudges, debris, and dust is uncovered.

- The slightest wrinkles or folds stand out.

To avoid issues with see-through labels, consider the following:

- Utilize clean label application practices minimizing human handling. Employ smooth, automated label dispensers over manual processes when possible.

- Inspect all transparent labels post-application and re-apply to remedy defects.

- Ensure label material and adhesives are appropriate for the container, whether it’s a flat surface, a curved surface, or a custom size or shape.

While clear labels beautifully reveal bottle and contents, they also highlight the slightest application flaws which could impact perceived quality. Invest in tight quality controls over label management and equipment. This includes selecting labels with a permanent adhesive that ensures a secure bond to the smooth surface of the container, preventing peeling or displacement that could detract from the product’s aesthetic appeal.

Find the Right Printing Company for Your Clear Product Labels

Now that you know how to prepare for clear or transparent labels, you still need the right company to help you pull off your see-through vision. At Blue Label, we have the tools and expertise to develop high-quality labels and see-through packaging with your specific needs in mind. You know your products and we know label printing. Together, we can make sure that your labels compliment your products and make people notice your brand.

Ready to wow your customers with eye-catching product labels? Contact Blue Label today to talk to one of our experts about clear printed labels or your next label project.