Screen Printed Labels

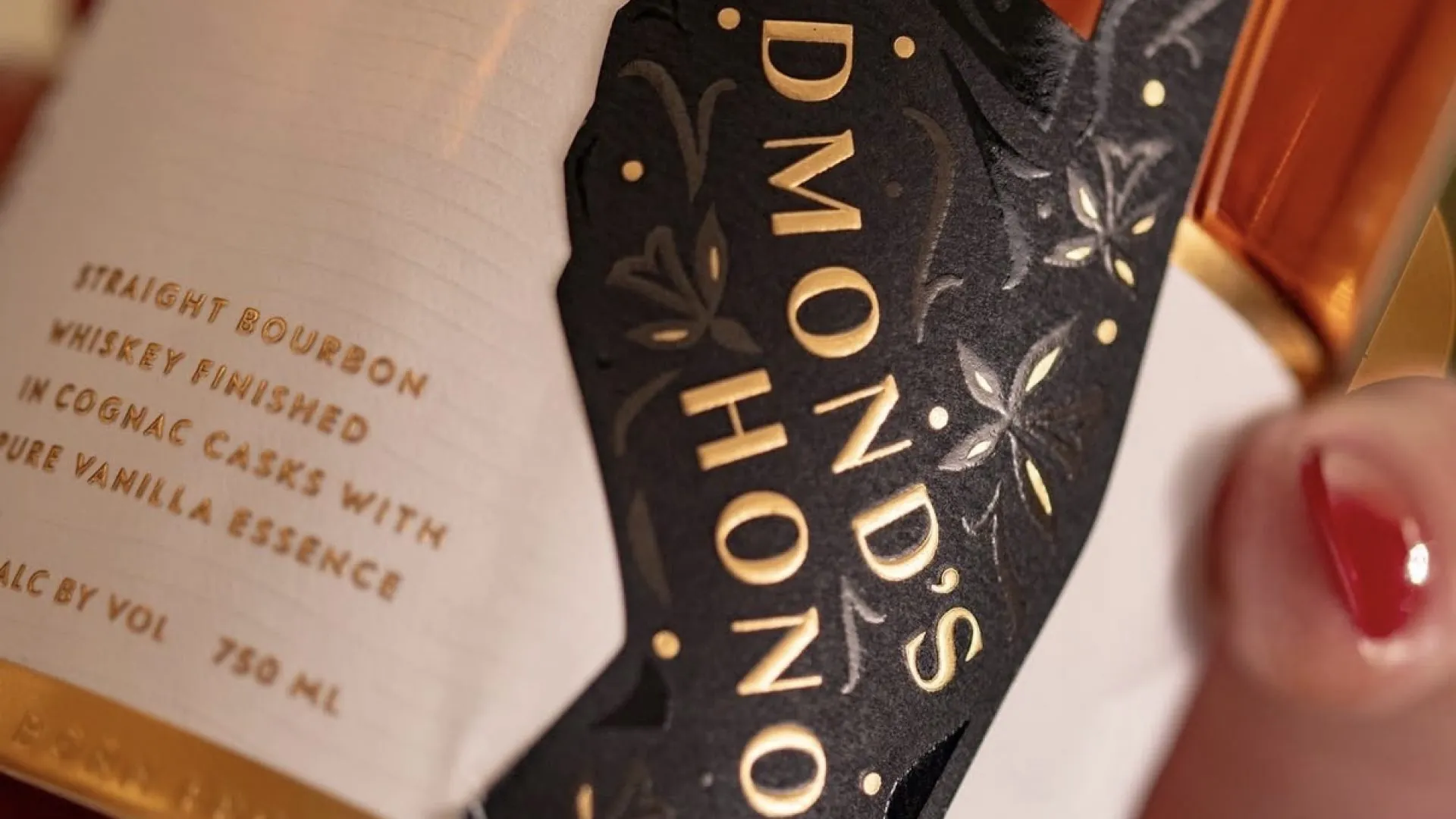

Edmond's Honor

Screen Printed Labels

When you need to make your labels more appealing, high build, Screen Printed finishing can take your packaging to the next level. That’s why Blue Label Packaging Co. offers quality screen printed, pressure sensitive labels for businesses that need their products to make a statement to consumers.

The Benefits of Screen Printed Label Printing for Your Business

High build Screen Printed is a powerful embellishment tool used to decorate your labels. Once your Screen Printed labels are printed, Blue Label can apply a special resin on top of your labels that cures under a UV light. Once the liquid hardens, it creates a high-gloss layer that your customers can see and feel.

As you may expect, Screen Printed finishing can make your labels more intriguing in a variety of ways. High build screen printing offers a variety of benefits for your product labels:

- Screen Printed printing literally adds an extra dimension that gives your labels a 3D look that customers can see from afar.

- Customers can feel the difference Screen Printed label printing, making your products more interesting to the touch.

- The gloss look of a cured Screen Printed resin stands out more aggressively than flat inks.

- Cured Screen Printed resin is abrasion and weather resistant, making sure your design is built to last

- Screen Printed finishing can help highlight key label design elements, drawing customers eyes to key details like text, logos, or other elements.

Why Blue Label

Fast Production

We pride ourselves on speedy production and shipping times, producing your printed labels in 5 business days or less*.

Quotes in 24 Hours

Blue Label Packaging sets the bar for responsive service, providing customized quotes for custom label printing jobs in less than 24 hours.

Label Expertise

Our label experts are involved in every step of the process, from helping you choose the perfect label materials to monitoring your custom label projects through all steps of the production process.

No Minimum Order Quantities

Because we work with businesses of every size, we require no minimum order quantity. Get the exact number of labels you need.

Frequently Asked Questions

Copy

Preparing your artwork for Screen Printed printing helps your labels print correctly and look professional. Don’t worry—it’s simpler than it sounds! Here’s what you need to know to get started:

-

-

- Use High-Resolution Art Files: Make sure your art files are high-quality (vector files like AI or high-resolution PDFs work best).

- Consider the Background Material Color: Screen Printed printing often uses layers of ink that interact with the material underneath. If your design includes a transparent or negative image effect, think about how the background material color will influence the final look.

- Account for the Screen Ink Layer: For designs requiring a textured or tactile finish, include details about any additional screen ink layers you want. These add that extra touch of elegance, especially on premium products.

- Design Around a Die Layer: If your label design uses a die layer for background colors, make sure it contrasts well with the printed design to make the image pop.

- Include a Negative Image, if Applicable: A negative image design (where the unprinted areas form the design) can be striking, but it requires careful planning. Highlight these elements clearly in your art files.

-

Copy

We offer shipping through several vendors like UPS, Fedex, and USPS. Ground, Next-Day, 2-Day, 3-Day, and custom freight options.

Copy

Our preferred file formats are Adobe Illustrator or High-Resolution PDF. You can view our complete artwork file standards checklist here.

Copy

Before printing your custom Screen Printed labels, we will provide a digital proof via email for your approval. This allows you to review your label, confirming details like positioning, color accuracy, text legibility, and more, prior to full production. We are committed to ensuring your complete satisfaction through this streamlined proofing process.

Copy

While Blue Label Packaging does not directly offer label design services, we do have resources to help with your custom label design needs. We maintain a directory of Blue Label Approved designers who specialize in label design and understand the unique requirements and technical details involved. We also showcase a gallery of label designs for inspiration.

Copy

Our printers are capable of matching up to 97% of the full color spectrum, allowing us to achieve precise color reproduction for your beer labels. We use advanced CMYK printing to produce an extensive gamut of colors. For designs requiring an expanded range, we also print using WOVG ink sets which add white, orange, violet and green.

Our top-of-the-line color management program and processes ensure we hit the correct hues, tints and shades. We color calibrate and profile all of our presses so your unique color palettes and gradations print true to your vision.

*standard labels are printed within 5 days after artwork approval