What are Embossed Labels?

⚞ The Highlights:

- Embossed labels are created with a process that raises or recesses parts of your design to give your packaging a premium, tactile finish

- They add depth and texture to your label, making your product stand out on the shelf with a more upscale look

- When planning for embossing, check that your label material and design details are compatible with the process to ensure clarity and durability

Who doesn’t want their labels to pop on the shelf? We know that when you’re creating consumer products—from beer and wine to cosmetics and cannabis—every detail matters. Embossed labels aren’t just about looking good; they add a tactile element that can influence buying decisions and boost your brand.

In this post, we’ll walk through what embossed labels are, how they’re made, and why they’re a smart investment for your products.

What Are Embossed Labels?

Embossed labels feature raised designs or lettering that give your labels a three-dimensional look. By pressing a custom pattern into the label material, you not only catch the eye but also invite customers to feel the difference. This technique is popular for products like wine bottles, beauty items, and much more.

“Embossing adds a tactile dimension that transforms a product from merely being seen to being experienced.”

How Are Embossed Labels Made?

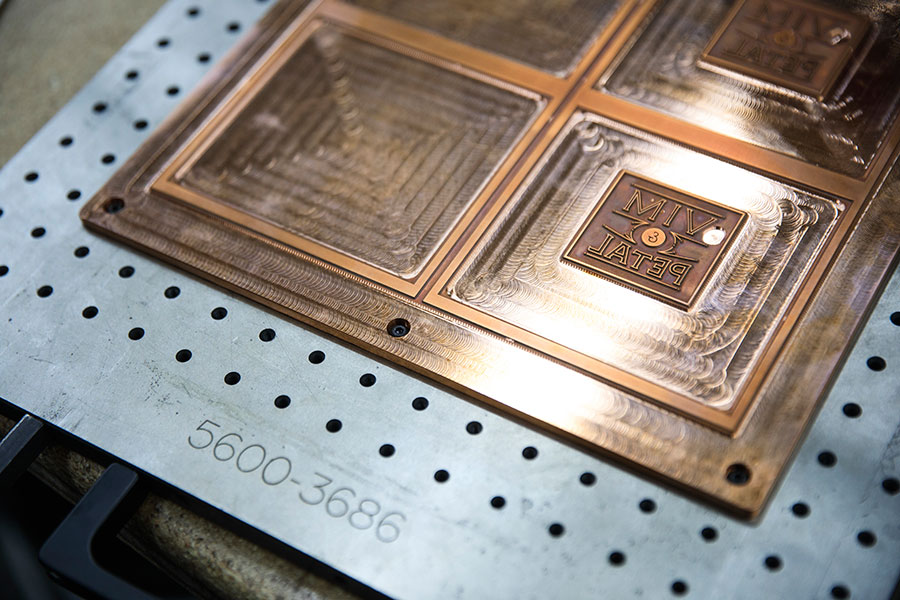

We begin by crafting a custom die—basically a specialized metal tool that brings your design to life by imprinting it onto your labels. Here’s a closer look at our process:

Custom Die Creation

We design a custom die based on your specific requirements (imagine it as a tailor-made metal stencil). This tool can capture everything from individual lettering to intricate patterns or even an all-over design.

Pressing Process

Next, the die is pressed against each label, so your design comes out raised and uniform every time. We often pair this with hot foil stamping—where heated, metalized foil is applied to the raised areas to create extra contrast and depth.

(Hot foil stamping really makes the design pop.)

Artwork Preparation

For the best results, your design files should be high-resolution (at least 300 DPI) and saved in the right format (typically AI, EPS, or PDF). This helps every detail be captured accurately during embossing. Follow our artwork guidelines closely to avoid hiccups during production.

The Benefits of Embossed Labels

We’ve seen firsthand that embossed labels can really boost your product’s appeal and help set your brand apart. Here’s why they’re worth considering:

Enhanced Aesthetics and Tactile Appeal

When customers can see and feel the detail in your label, it reinforces the premium quality of your product. Research in the Journal of Marketing shows that packaging encouraging consumers to touch can increase purchase likelihood.

Increased Shelf Impact

In a crowded retail space, the added texture and depth of embossed labels can make your product stand out. Studies from Bocconi University and the University of Innsbruck suggest that tactile interaction often sways consumer choice in visually busy settings.

In fact, some industry studies suggest that premium packaging—like embossed labels—can boost consumer interaction by as much as 12% in markets such as cosmetics and spirits. It’s impressive to see how a little extra texture can make a big difference!

Design Considerations and Artwork Preparation

We know that adding embossed labels to your production line might raise some technical questions. Here are our best practices to help you get it right:

- File Specifications: Stick to high-resolution files (at least 300 DPI) in AI, EPS, or PDF format so your design translates perfectly during embossing.

- Design Limitations: Keep your design bold and simple—overly intricate patterns might not emboss well and could lose clarity.

Cost Analysis and ROI

We get it—cost is a big factor. Here’s a closer look at the numbers:

Production Cost Breakdown:

- Die Creation: Custom dies need an upfront investment, but that cost gets spread out over large runs.

- Material Selection: The substrate (the base material, like paper, synthetic films, or eco-friendly options) you choose affects both the look and durability of your labels.

- Labor & Finishing Processes: Extra touches like hot foil stamping add to the cost but also boost that premium feel.

Considering Return on Investment (ROI)

Investing in embossed labels can allow you to charge higher price points and improve shelf impact. Some industry studies indicate that premium packaging can boost consumer interaction by up to 12% in competitive sectors like cosmetics and spirits. A Smithers Pira report even suggests that embossed finishes can drive a 12–15% lift in engagement.

Did You Know? If a custom die costs $1,000 and you produce 10,000 labels, your cost per unit for the die might be just $0.10—a small fraction compared to the potential sales boost from enhanced packaging.

(Remember, your actual ROI will depend on your production scale and market conditions, so it’s a good idea to run your own numbers.)

Material Selection, Compliance & Sustainability

When it comes to choosing materials for embossed labels, here are a few things to consider:

- Substrate Options: Not every material embosses equally. Your substrate—the base material of your label—could be paper, synthetic film, or an eco-friendly alternative. For example, synthetic film might be great for durability in tough environments, while eco-friendly paper appeals to sustainable brands.

- Regulatory Compliance: If you’re in a regulated industry (like food, beverages, or cannabis), it’s essential that your labels meet all the necessary standards. Our labels are designed to comply with guidelines such as FDA requirements for food packaging. We work with you to ensure your embossed labels are fully compliant.

- Sustainable Practices: More brands are opting for eco-friendly options. We can help you choose sustainable materials and production methods—like using FSC-certified paper or Green Seal-approved processes—that match your environmental goals without compromising quality.

How to Choose a Reliable Embossing Partner

Finding the right partner is as important as nailing your design. Here’s what you should look for:

- Proven Expertise: Look for a partner with a solid track record in producing high-quality embossed labels. Check their portfolio, certifications, and testimonials.

- Customization Capabilities: Your design should come to life exactly as you envision it. Work with a partner who offers consultative services, samples, and test runs.

- Efficient Turnaround: Time is money. Choose a supplier who can meet your production timelines without cutting corners on quality.

At Blue Label Packaging, we’re all about quality and speed. We’re proud of our quick turnaround times and the way we work side-by-side with you to nail every detail.

Ready to Emboss?

If you’re excited to see how embossed labels can transform your product’s packaging, we’re here to help. Contact us today to discuss your project, review cost breakdowns, and learn how we can work together to make your labels—and your products—truly unforgettable.

Glossary of Terms

- Custom Die: A specialized metal tool used to imprint a design onto the label material.

- Hot Foil Stamping: A technique where heated, metalized foil is applied to raised areas of a label to create contrast and added depth.

- Substrate: The base material of a label, such as paper, synthetic film, or eco-friendly alternatives.

- Calibration: The process of adjusting equipment settings to ensure consistent quality in production.