Online Alcohol Packaging: How to Prepare Your Wine and Spirits Labels for Ecommerce Success

Online sales of wine and spirits have steadily increased over the years, making the digital market a prime place for vintners and distillers to sell their products. That trend took off even further when wine ecommerce and other online alcohol sales jumped 234 percent during the COVID-19 pandemic.

Whether you use a third-party marketing platform or sell wine or spirits directly from your website, it’s important to make sure your custom labels are just as effective on smartphones and monitors as they are in stores. Fortunately, there are some steps you can take to help your wines and spirits succeed online.

4 Tips for Online Wine and Spirits Labels

The average consumer already has an incredibly short attention span – that attention span only grows shorter online. When you have roughly eight seconds to make an impression, a great product label can be your best friend.

It’s important to remember that certain aspects of your label may not translate well online. As such, you’ll want to keep ecommerce in mind when you put together a label design for your wine or spirits. Here are five ways that you can help set up your wine and spirits labels for online success.

Color them impressed

A bland bottle typically doesn’t sell well in online stores. A pop of color is one key element that catches ecommerce users’ eyes. A flash of red or a burst of yellow can stop a consumer from aimlessly scrolling past your products so that they will check out what you have to offer.

In terms of what colors to use, it really depends on what type of message you want to send. Colors can influence consumer’s emotions by making them associate with certain feelings. For example, a green label can inspire feelings of relaxation and happiness. Meanwhile, red signifies strength or power. Try to find a color that helps you tell your product’s story – just make sure it’s something that really stands out in an ecommerce store.

It’s also important to note that while vibrant colors can help you stick out in a crowded ecommerce store, too many colors can have the opposite effect. Labels with multiple interlocking colors can appear muddy in a small image. In addition, certain color combinations can help your label pop out to consumers and make it easier to read the text. A color wheel can help you identify opposite colors that still work with each other. Test out how your potential label would look in a product image to make sure it’s just as stunning online as it will be in person.

Clearly identify your wines and spirits

Once you have someone’s attention, it’s critical that users quickly identify your products. Any seemingly missing detail can lead an ecommerce customer to click away to a different product.

Make sure users can immediately recognize your brand name and product designation. While these details may seem prominent in your design, consider how easy it would be to read them in a small product image on a phone screen or monitor. Amplifying these details will help users recognize who you are and what your product is, be it a malbec, a straight rye whiskey, or something else.

Make a big impression

A lot of small, ornate details may look great in person, but it may get lost in a small product image nestled amidst dozens of other bottles. If you want your wine or spirit to truly stick out in an ecommerce setting, it’s time to amp up your design.

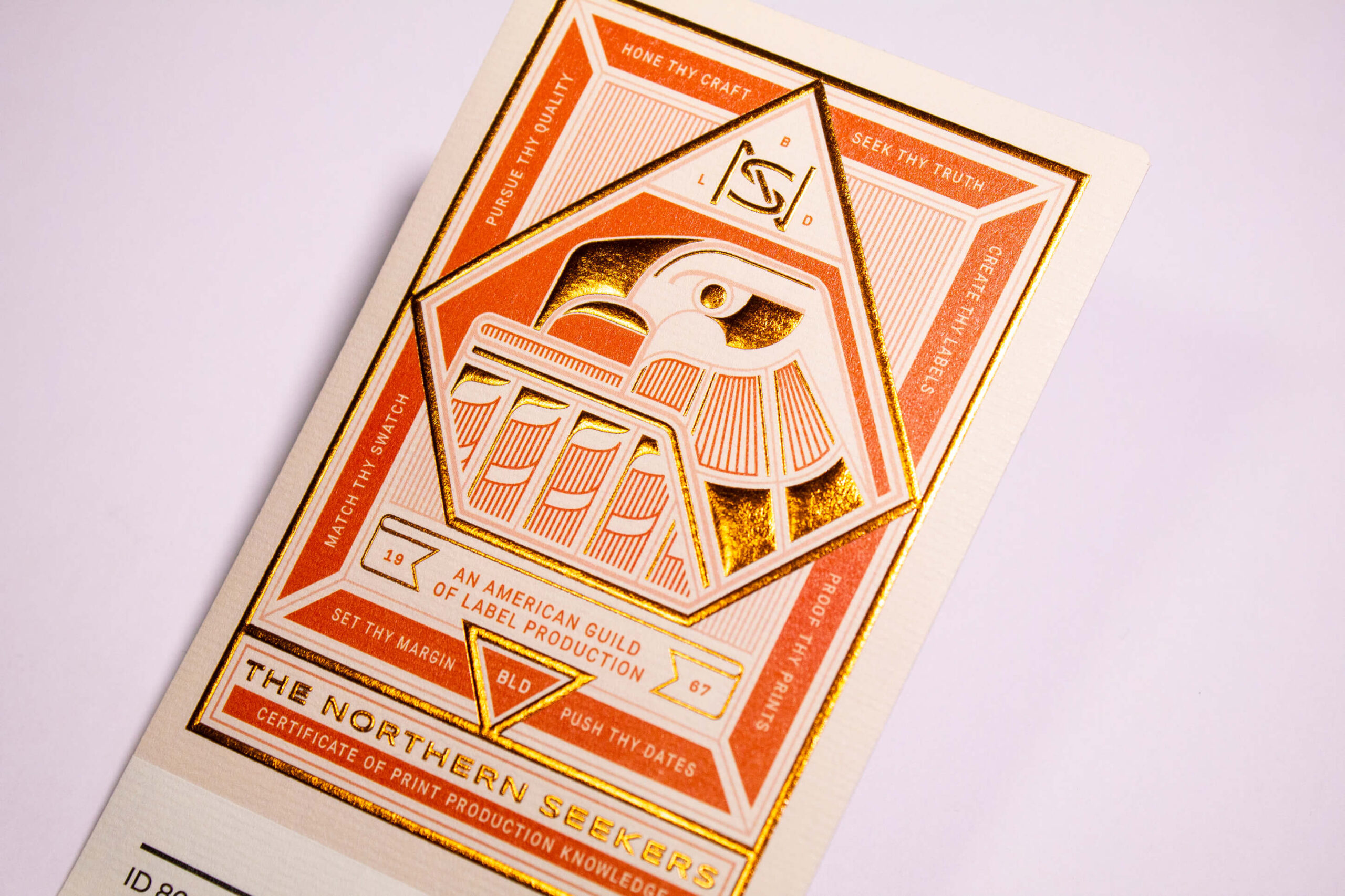

There are a few ways that you can go about enhancing your design. As mentioned earlier, large pops of color are one way to make an immediate impression. There are also special printing capabilities that can add an extra dimension to your design. Utilizing hot foil stamping is one way to make your wine and spirits labels look more sophisticated, elegant, or flashy for anyone who scrolls by your products.

While small design details might not show up on small product images, that doesn’t mean you should abandon them altogether. These elements can still make an impression on customers once they receive their bottles. A rougher paper wine stock or an embossed pattern may not show up on screens, but it can add an extra dimension to wow consumers once they get a hold of your bottles.

Follow barcode best practices

While your design is a major factor for ecommerce success, it’s critical not to forget about another key purpose of your wine and spirits labels. Online retailers typically require product labels to include Universal Product Codes (UPC) for scanning and identification purposes. As such, you’ll want to ensure that you follow barcode best practices for your wine and spirits labels.

If you’re not careful, you may accidentally set up your barcodes for failure. There are a few steps you can take to make sure that your barcodes are ready for business.

- Maintain a quiet zone. Make sure that the area around your label’s barcode is clear of any texts, graphics, or other printed elements.

- Use a simple color scheme. Try to avoid warm colors that won’t work well with red lasers. The safest choice is to stick with black text on a white box.

- Utilize proper barcode sizing. Keep your barcode somewhere between the minimum and maximum recommended barcode sizes.

- Minimum – 1.175” wide by .816” high

- Maximum – 2.938” wide by 2.04” high

- Send barcodes in the right formats. Once your label design is ready, you’ll need to send a few of your barcodes to your printing company in a few different forms.

- An image file of the barcode you’ve received from the provider

- An Excel document with a list of UPC numbers

- A PDF or EPS of the barcodes

Find the Right Printing Partner for Your Wine and Spirits Labels

Once you have your labels ready for online success, it’s time to find a label printing company. At Blue Label, we have the experts and technology to help you get the most out of your packaging.

Our team strives to not only enhance your designs, but also make sure that everything is right before we print your full order. We can work with you to check your art files and identify the best, most cost-effective solutions for your wine and spirits. Contact us today to invest in stunning wine and spirits labels.