10 Beautiful Label Designs and the Designers Behind Them

(more…)

Of all the decoration techniques, hot foil stamping stands out as the most effective. At a relatively low cost per piece, gold, silver, and other types of foils can be used to create outstanding, multifaceted compositions very economically. We’ve compiled five hot foil label projects that we had a lot of fun working on to demonstrate the versatility of foil stamping, especially when used in combination with digital printing.

If you are in the craft spirits industry, you know that the competition has gotten more fierce in recent years. More small brewers and distillers are entering the game, and setting yourself apart is the only way to capture a narrow — but rapidly growing — market. While you have to make a smooth concoction to keep loyal customers coming back, sparking that initial interest is a bit more difficult. Unique, eye-catching labels help to garner interest in your brand that can quickly grow into a loyal following.

Here are trends in labeling that you should consider as you decide on the alcohol bottle label design for your craft spirit labels.

Many people believe that color psychology is a key factor to consider when designing your product’s label. The thought of color experts is that colors have the ability to send messages by influencing consumer’s emotions through a stunning label. When color psychology is applied correctly, businesses competitively position themselves in the visual market, which shows the importance of color in packaging.

Color selection, then, is a vital part in the design process of a custom label. Here are 3 color psychology insights that attract customers for your product’s label design.

To help you remain ahead of your competition, we thought we would take a moment to review a few of the label design trends shaping the landscape.

(more…)

Borders frame the image, add an air of decoration to the composition, and are traditionally an important part of design. Basically every great work of art has a border (a frame) that accentuates the work, so why wouldn’t you give the same treatment to your label? Well, there is one very important reason.

When building the vision for your unique beer bottles, you can learn a lot from what’s been done in the past. If you want a vintage look for your craft beer, antique beer bottles like these can inspire your design. And as mentioned in a previous blog post, it’s not just the label that can set your beverage apart from others. It’s the container type, too.

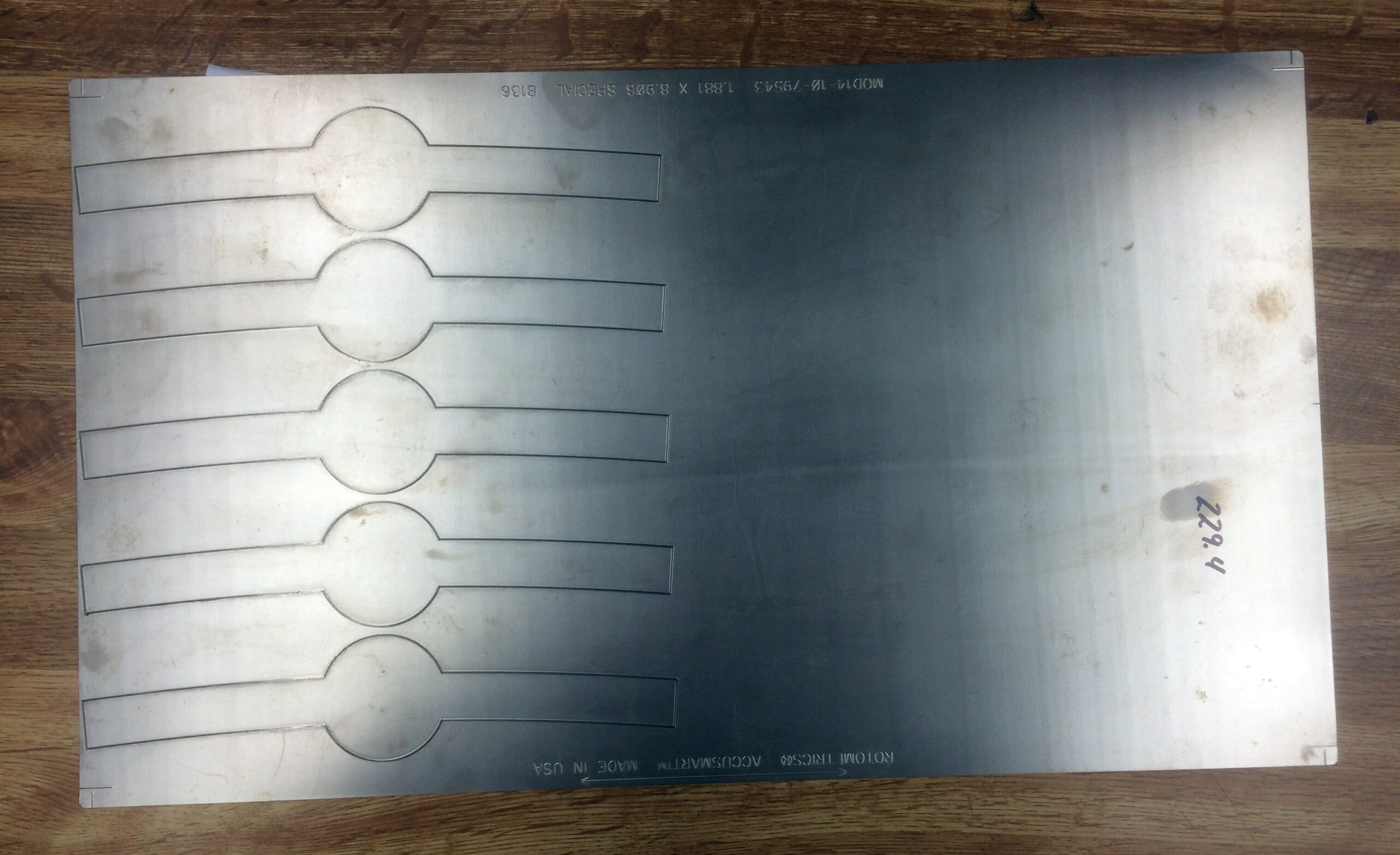

There can be a lot to think about when considering die cut label printing. From the costs of purchasing a custom die to creating your desired shape, it can be confusing for anyone who isn’t well-versed in die cutting. To help simplify the process, we outlined some of the basics when it comes to creating a custom die cut label.

“We don’t have that die.” “Make sure you check the die line.” “You might need a custom die.” You may have heard these phrases in conversations with your label printer. Well when a label converter is talking about dies, it can sound a bit like a game of Yahtzee. Let’s start with some basic die cutting definitions:

When working with a label converter, you may be wondering if you need a custom die to create your label. The answer to this question will depend on the shape you are trying to achieve and the dies your label converter already has in stock.

At Blue Label, we have a stock of over 2,000 different dies that we have accumulated over the years, which includes most common shapes (different sized rectangles, squares, circles, and ovals). We also have some distinctive shapes, like triangles and diamonds. However, if you want something that is specific to your brand, like a label in the shape of your logo or a label that fits a piece of custom packaging, you’ll likely need a custom die.

First, start by measuring the surface you have to affix the label to. For instance, if you have a 12-ounce bottle, you’re not going to want a label much bigger than 3 ½” by 7 3/8”.

Once you know your size constraints, you can begin to design the shape. Make sure you stay away from sharp corners and acute angles; these can cause tears when the matrix is being stripped away.

After you have decided on your shape, convert it into a line in Adobe Illustrator using the “Average” command. To do this:

It is very important that it is a joined line (not a bunch of overlaid segments) so that the die is continuous. Make sure the die is the correct size, and then overlay it on the Illustrator file that contains your artwork. Name the die line as a specific spot color, and make sure it is on its own layer.

The average die costs around $150, but it really depends on the size and shape of the label. If you have a label that is a complex shape (a lot of corners and curves), the die could cost more. The cost of a die is also determined by how many individual labels are on each sheet of the die (these are called cavities). If you have a very small label, the price of the die could also increase.

At Blue Label, we pass the cost of the die directly on to you without markups. So, when we recommend a custom die, you can trust that we are doing it with your best interest in mind when you order die cut labels.

Yes, any custom die you order is yours. That being said, the die you purchased is formulated for a specific piece of manufacturing equipment, mainly, our ABG Digicon 2. So even if you were to leave us (and we hope not), you’ll have to make sure your die will work on other converters’ equipment. But we will send it to you regardless.

Once we have purchased a die, we will replace it when it wears out or if it is damaged. You will only pay for each die once as long as you are our client.

This is just a basic overview of dies, there is a lot more to know, like corner tolerance, minimum and maximum thicknesses, how material choice effects die formulation, who makes dies, etc. We will cover some of this in future posts, but you can always contact us if you have additional questions regarding dies (or anything else about labels for that matter).