Label Decoration Breakdown: What’s Available and How They Enhance Your Design

Spot Varnish

How spot varnishes work

Label varnishes are a protective liquid coating that can help protect the surface of your label and highlight certain features of your design. Varnishing liquids are rolled onto your labels and cured or dried. This process causes the varnish to fill in any nooks and crannies of your label’s surface material, which is especially good for paper materials. While varnishes can coat to the entire label, spot varnishes are applied to specific parts of your design.

How spot varnishes enhance your label

As we just mentioned, spot varnishes are a tremendous way to highlight aspects of your design, such as your logo, an illustration, or some other detail. Spot varnishes come in different forms, such as gloss, satin, and soft-touch. Each option can add a different look – or even feel – to individual parts of your design, which can help attract the attention of discerning consumers.

Hot Foil Stamping

How hot foil stamping works

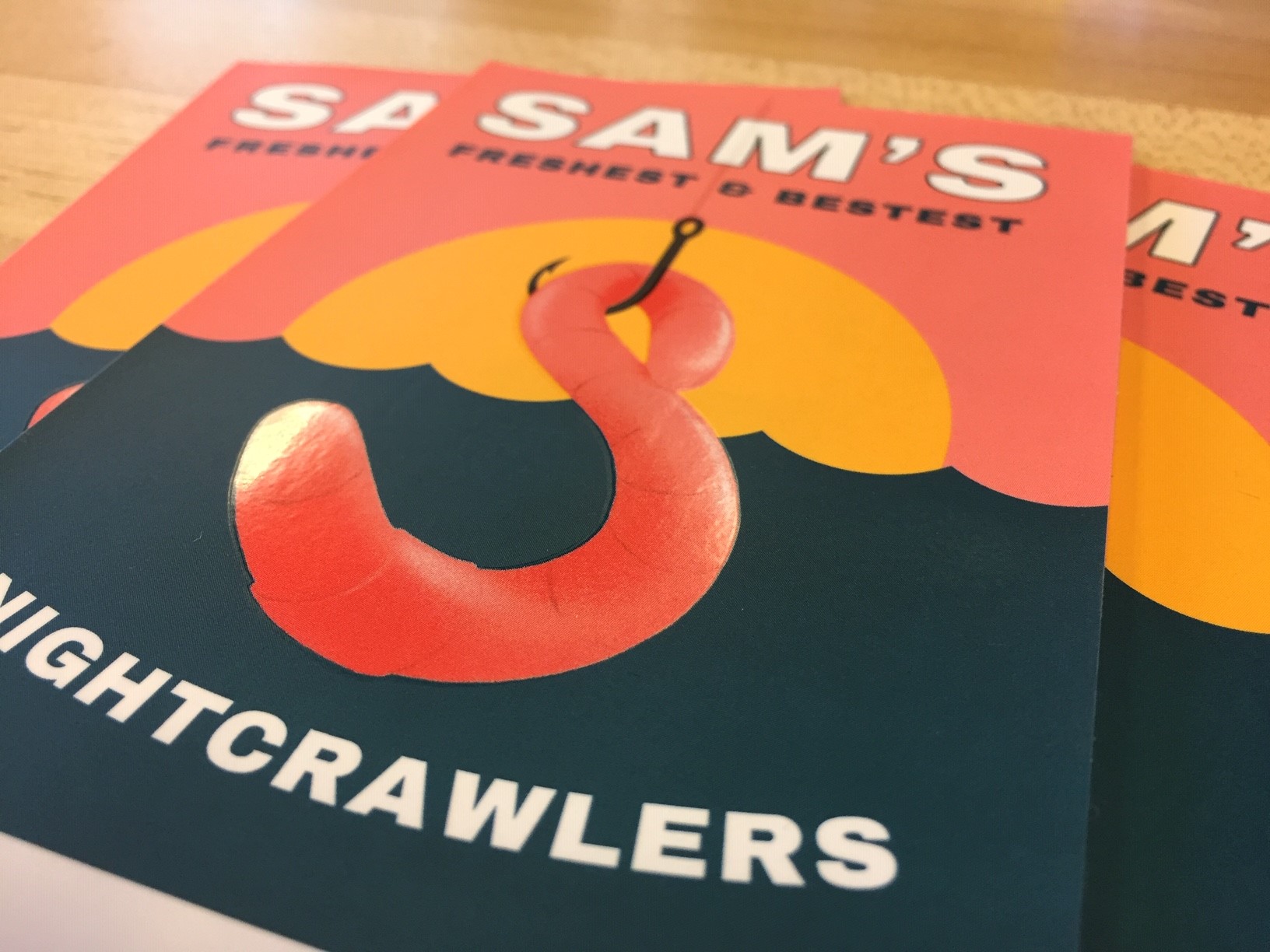

Hot foil stamping is the process of pressing a foil, often metallic, into your label material. During this process, an engraved plate is heated up and used to stamp a metalized foil or film into your facestock of choice. The combination of pressure and heat allows the foil or film to stick to your label material with the dry ink in between them. As a result, the engraved design of the plate is left on the label to add a special decorative effect.

How foil stamping enhances your label

Hot foil stamping is an extremely versatile method for label decoration. By pressing engraved foil or film patterns into your label, you can create outstanding, multifaceted compositions that look expensive without drastically driving up printing costs. While hot foil stamping is commonly associated with gold and silver sheens, there are hundreds of different types of foils and films available:

- Metallic (gold, silver, etc.)

- Gloss

- Matte

- Holographic

These various foils and films give a plethora of design options for your labels. Trying to market your product as a high-quality good that’s worth a higher price point? Gold and silver borders and accents can help your packaging look as high-class as your product. Simply want to make your label look really cool. Holographic films can pack a visual punch that can make sure your label gets noticed. Between different foils and engraving possibilities, hot foil stamping offers plenty of potential for your packaging.

Embossing

How embossing works

The embossing process involves pressing an image into the label material. Custom dies are made with a specific pattern – common embossing patterns highlight individual lettering, borders, and specific decorations. The embossing die is physically pressed into your labels as your label is finished. This process creates an imprint that rises above the rest of the label. Embossing can also be combined with hot foil stamping to create a three-dimensional image that users can both see and feel.

How embossing enhances your label

To start, embossing allows your labels to literally stick out more than before. Embossing adds texture that makes products look more sophisticated than the usual flat surface. Combining the raised surface with hot foil stamping adds some complexity to your design. This look can in turn add some intrigue or help improve the perceived value of your products.

Another major benefit is that embossing changes the tactile experience of your products. Research shows that “packaging that encourage[s] people to touch the product may increase the likelihood that consumers will make a purchase.” By embossing a pattern onto your label, consumers can feel the difference between your packaging and less impressive products.

Upgrade Your Packaging Through Label Decoration

A well-decorated label is an impressive sight for potential customers. The right digital printing company can open your packaging up to new design possibilities. At Blue Label, our experts work with you to uncover new label decoration options like spot varnishes, hot foil stamping, and embossing to enhance your design so that you can wow your consumers.

Ready to improve your packaging through cost-effective label decoration? Contact us today to talk to our team about your next label project.