What are Embossed Labels?

- alcohol labels

- bottle labels

- craft spirit labels

- embossing

Label embossing is a special technique that presses specific designs into your labels, thus making them actually “stand out” from the typical flat label surface. This capability is a popular feature for a variety of products, such as wine labels, health and beauty labels, and other options.

How Are Embossed Labels Made?

To emboss a label, a specific pattern is pressed into a label material. The individual patterns will differ depending on the desired look of the label, which can include individual lettering, a specific decoration, or and entire custom design that covers most of the finished label.

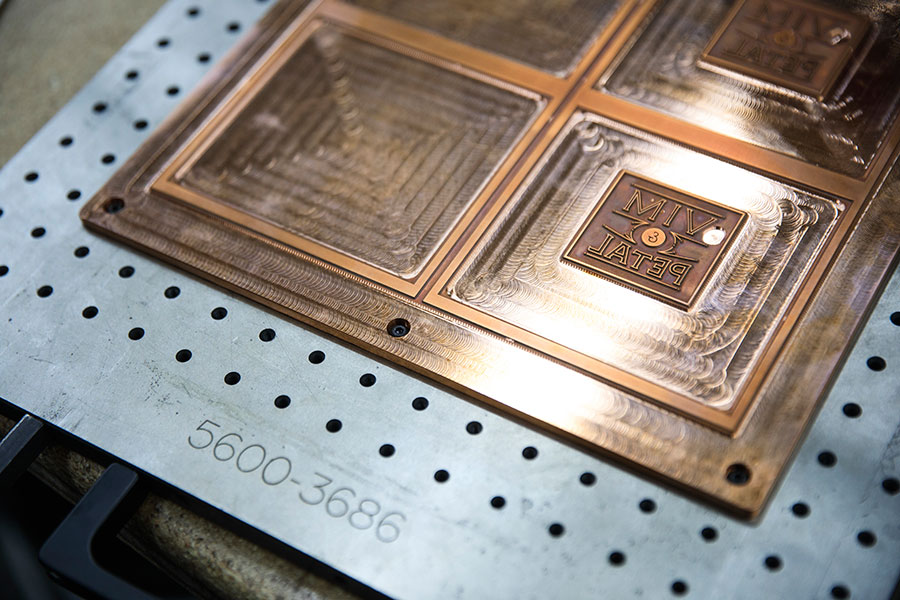

These patterns need to be physically pressed into the labels. This is done with a custom die that is designed with the pattern of choice. During the printing process, the embossing die is pressed against each label, leaving the desired imprint. While embossing can be done by itself, it can also be paired with hot foil stamping to add an even more dynamic look to your embossed labels. In this process, metalized foils or films are pressed onto your labels, allowing you to further highlight the embossed parts of your design.

Why Are Embossed Labels Effective?

When you want to add some flair to your labels, embossed labels are a game changer. The resulting look gives labels a more sophisticated appearance while adding a three-dimensional look and feel to a product. All the little details that are pressed into the label add a level of complexity to your design, which is a perfect fit for anyone who wants to market their products as a high-quality option.

Not only can people see the difference, they can also run their fingers across the label and feel the individual indentations left from the embossing process. That sense of touch can make a big difference when it comes to someone making a purchasing decision. Research that was published in the Journal of Marketing suggests that “packaging that encourage[s] people to touch the product may increase the likelihood that consumers will make a purchase.” In turn, embossing invites customers to pick up a bottle to see–and feel–what’s different about it.

This effect may be even more important when it comes to products that sit on crowded shelves. According to studies conducted by researchers from Bocconi University and the University of Innsbruck, “when the visual array is overcrowded, the hands have an even larger influence on product choice.” When your product shares space with dozens of other competitors, that edge can be the difference between being sold and remaining on a shelf.

Find a Printer That Can Emboss Labels

Embossed labels can be a great option for your labels, but it won’t be an option without the right label printing company. At Blue Label, we have the experience and printing technology it takes to create high-quality, embossed labels with short turnaround times. Contact us today to talk to one of our experts about how label embossing can make an impression on your customers.