Holographic Labels: 4 Design Tips for Stunning Product Labels

When you have seconds to command consumers’ attention, holographic labels give you the means to keep all eyes on your products.

Holographic label materials are an increasingly popular packaging choice for good reason – these shimmering substrates add a whole new dimension for craft beer, specialty foods, and any other products in need of a visual spark. Let’s break down what goes into a holographic label and what you can do to get the most out of your packaging.

What are Holographic Labels?

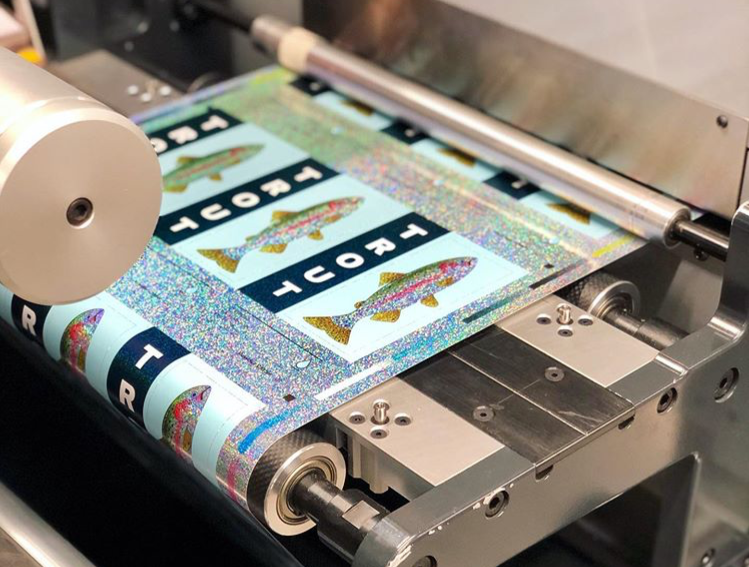

The name “holographic label” comes from the iridescent effect these labels have on your packaging. The iridescent labels are made with a special film that creates a rainbow-like effect that allows your design to shimmer. Ink is printed on this holographic label material and protected with a laminate to protect your design. This helps protect your labels from scuffs, water, and any other potential hazards.

It’s also important to note that there’s a difference between holographic labels and hologram stickers. A security hologram is a sticker made with serial numbers or logos. Hologram labels are hard to counterfeit, so brands can use them to show authenticity and ensure original product protection. Holographic labels simply refers to the holographic effect of the material that the artwork is printed onto.

Holographic Label Design Tips

A good holographic label is a great way to attract attention. However, these materials can pose some potential design challenges that can impact the overall look of your label. Here are some key considerations to help you make your holographic labels captivate your customers.

Give the holographic label material room to shine

When you have something as stunning as a holographic label material, it’s important to think about empty space. Empty spaces on your label design allow the holographic effect to shine through without any obstruction from ink or other printed elements.

That empty space could be the entirety of your label that’s not covered in printed details like your logo and text – that’s certainly one way to create a stunning effect from all sides of your container. Empty spaces within design elements can also allow certain aspects of your design to pop out to customers. Both routes will certainly attract attention, so just make sure you give the label material the space it needs to show its magic.

Avoid additional gradients

While color transitions are visually appealing, there can be too much of a good thing. Holographic label materials already add that color-shifting rainbow effect to your packaging. Adding a gradient will only jumble up the color transitions of your label even further.

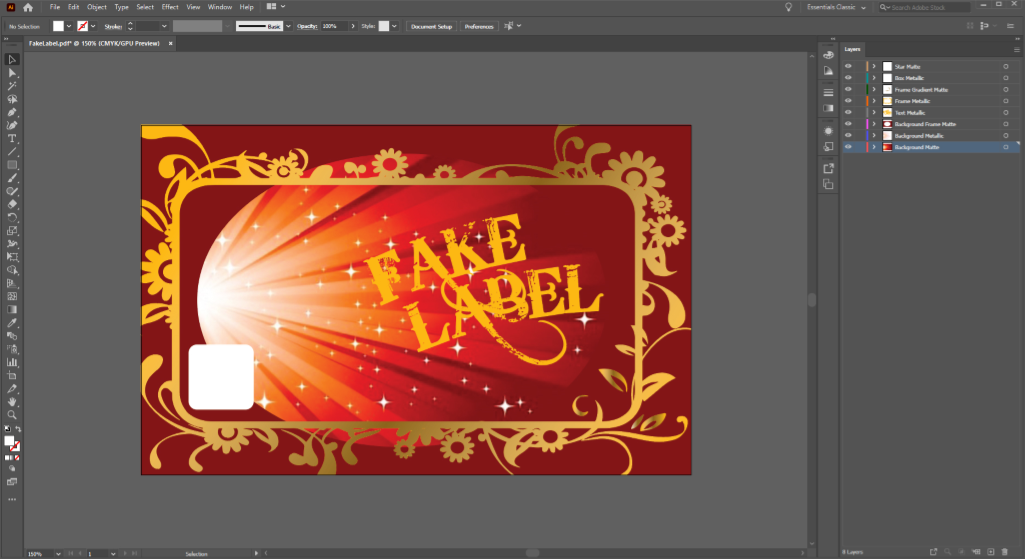

Use white ink to block out the holographic effect where needed

While that holographic sheen is certainly stunning, there are some elements that need to stand out on their own. Certain label inks are translucent enough that the holographic effect can show through details like text or logos if you’re not careful. As such, you’ll need to take measures to block out that effect for any areas that should be opaque.

If you need to block out the holographic effects, have your printer lay down white ink to create opacity on holographic substrates. You’ll need to include a specific layer called a white file in the art file to lay out exactly where this white ink should go. If you need more information on how to go about this process, check out our post on white file best practices.

Pair holographic label materials with the right laminates and varnishes

The last thing you want to do after investing in gorgeous holographic labels is to cover up what makes them special. Laminates and varnishes play an important role in both print protection and the overall aesthetic appeal of your product labels. However, certain laminates and varnishes are better suited for holographic labels than others.

Glossy laminates and varnishes are generally the best options for holographic label materials. The reason for this is simple – matte finishes will end up dulling the holographic effect. A glossy laminate or varnish will not only allow the holographic material to completely shine through, but also protect your ink from scratches, scuffs, and other hazards.

Invest in the Best Holographic Labels for Your Products

Holographic labels can add plenty of glitz and glam to your packaging whether you need a stunning can wrap or some other product label. Of course, you’ll need to work with the right label printing company to make sure you get the best, most cost-effective labels for your exact needs.

At Blue Label, we strive to do more than simply print labels. We work with you from start to finish to guide you through the printing process. From assisting with identifying the perfect holographic material to double checking your art files, we put in the time to understand your needs and add value along the way. Contact us today to talk to one of our experts about holographic, eye-catching labels for your products.