Restaurant Stickers: How Food Labels for Delivery and Takeout Orders Can Benefit Your Business

No matter whether you call it a label or sticker, these markers can make a difference for your business. Here are three notable reasons why you should invest in food labels for your takeout and delivery orders.

Food Labels Can Provide Useful Information

A good label is a blank canvas for potential information, both for you and your customers. A single sticker is an easy way for you to share key business information with every container – and in a very professional, attractive manner as well. For example, the following details could prove useful to your customers:

- Restaurant hours

- Phone number

- Website

- Social media pages

- Locations (if applicable)

Even though you’ve already completed a transaction, after an order, it doesn’t hurt to remind people how and where to contact you for their next order. Listed information can also prove useful for a new customer who had no idea they could follow you on social media or that you had a location near their mom’s house.

In addition to details like your phone number, stickers can also help you share information that’s custom to every order. A takeout label can easily include a blank space that’s designed for helpful features that would improve a customer’s experience. For example, a customer with a big order would probably appreciate it if each container had a sticker that listed what is in the container and when it was packaged. Sure, you could write it directly on a box, but labels look much more professional and act as a great way to include quality branding.

Food Labels Make for Extra Marketing Opportunities

Speaking of how labels make for more professional packaging, let’s talk about a key benefit of a good restaurant sticker: branding. Every takeout or delivery container is a marketing opportunity. Takeout and delivery labels are prime spaces to include your logo, color themes, and any other details that will resonate with customers. Any restaurant can slap a boring white sticker on a package and call it a day. Only yours can emblazon each order with your brand and get people excited before they open the container.

Another benefit of utilizing branded takeout labels is that it helps create a cohesive image for your business. From takeout containers to menus and signage, unified presentation is big for business. How big, you ask? One study estimates that consistent presentation of a brand can help increase revenue by 33 percent, so investing in some branded container labels can be a greater financial boon than you think. In fact, diehard fans may even appreciate an extra sticker or two in their bags – it never hurts to have your customers stick your brand in new places.

Food Labels Make Food More Secure

A good sticker offers do more than just look good and provide information. Restaurant labels can serve as tamper evident seals for delivery and takeout orders. That simple seal over the flap of a container can help protect food from devious delivery drivers. That’s a key safeguard with more people turning to delivery services like DoorDash and Uber Eats, especially since a 2019 study by U.S. Foods found that 28 percent of deliverers admitted to taking food from an order.

Even if you don’t rely on outside delivery people and trust your staff, the vast majority of customers still appreciate a tamper evident seal. That same study found that 85 percent of people would like restaurants to use some form of seal to protect their food. A simple seal can give your customers some peace of mind – and that’s something you can’t put a price on.

How to Get the Most Out of Your Takeout and Delivery Stickers

Even a single sticker can make a notable impact on your packaging. Of course, that doesn’t mean you need to settle for basic labels for your restaurant. Every takeout or delivery label is a chance to educate and impress your customers, so it’s best to get the most out of these miniature marketing tools.

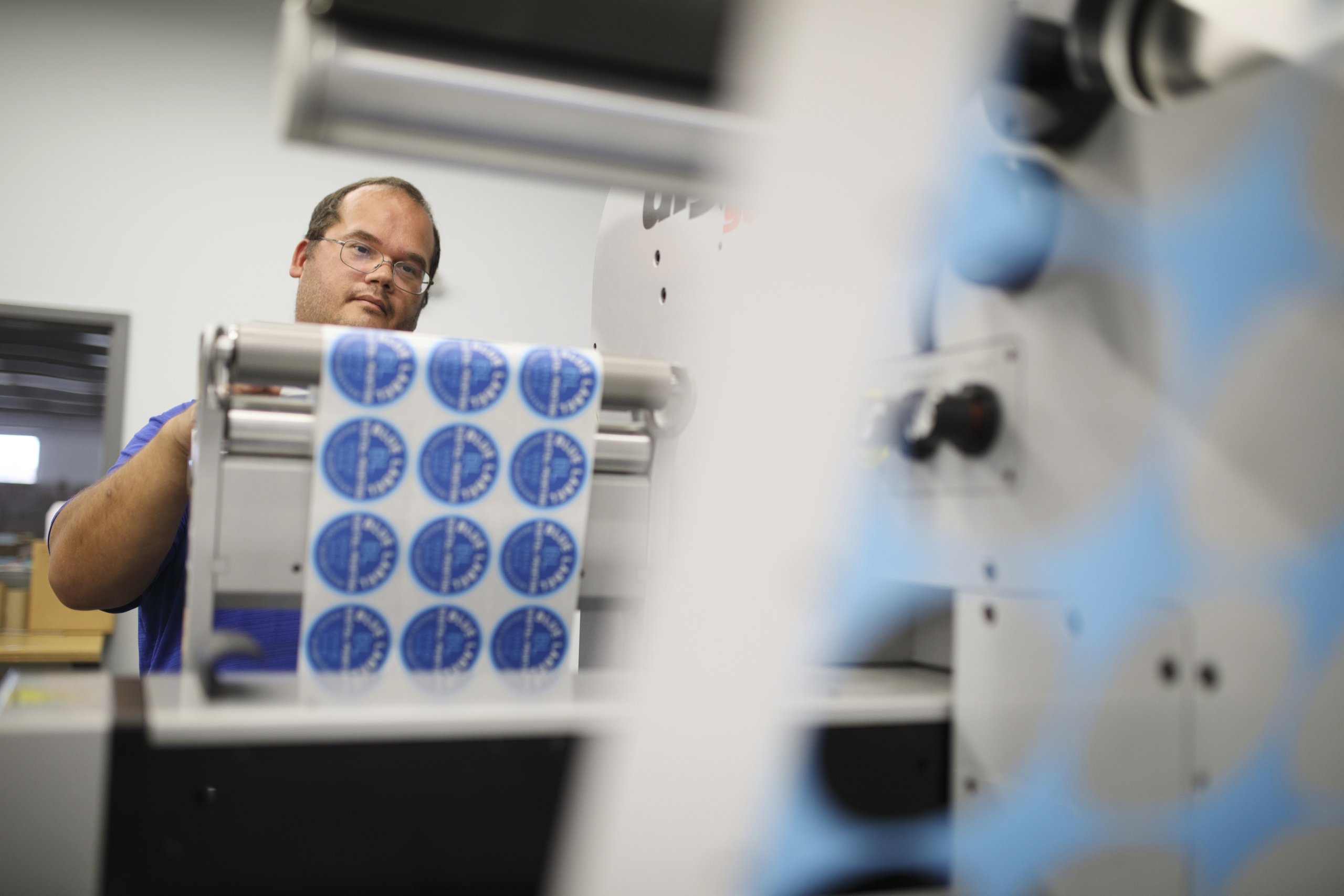

At Blue Label, we can help you enhance your labels without breaking the bank. If you really want to impress your customers, we can laminate to protect your artwork and add a textural element to your packaging. We can even utilize variable data printing technology to randomize certain elements – like different food items, slogans, or maybe pictures of your other menu options – of your labels and really spice up your sticker game. No matter what route you want to take, our experts can help you invest in stunning food labels for your to-go orders. Even better, our digital printing technology allows you to order labels in small quantities without sacrificing on quality and order flexibility.

Ready to amp up your takeout and delivery orders? Contact us today to talk to one of our experts about how we can help you improve your packaging.